G22A

KOTEN

G22A

Negotiate

1

T/T, L/C at sight

5sets/month

By strong seaworthy packaging

Within 30 days after get the deposit.

China

2575

| Availability: | |

|---|---|

| Quantity: | |

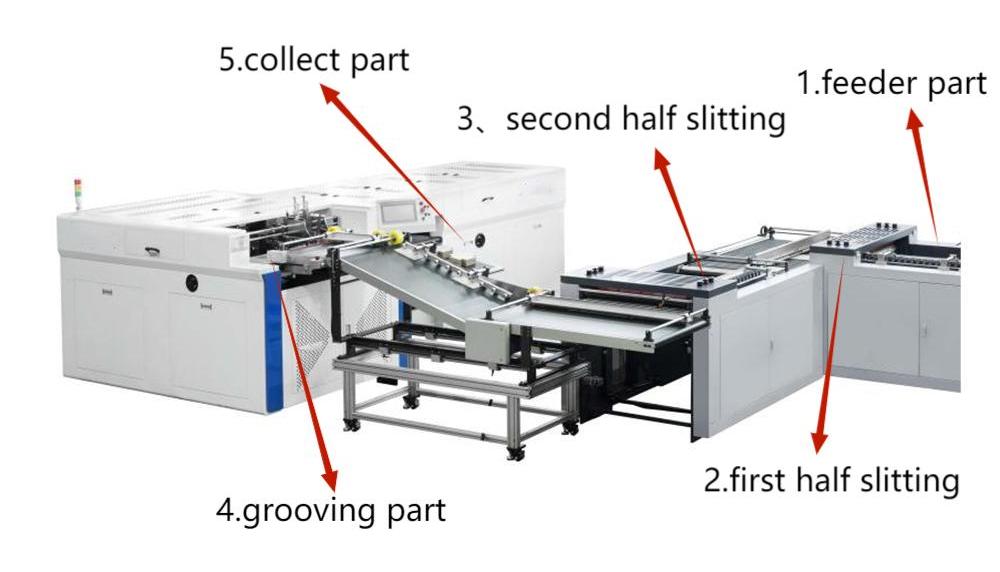

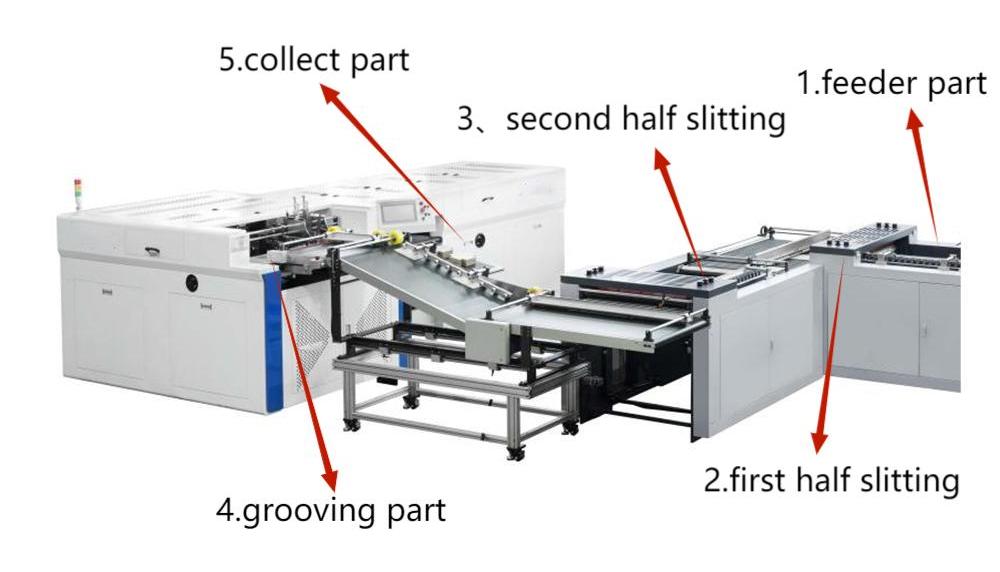

Automatic Grooving Machine and Corner removal for Rigid box(R22A)

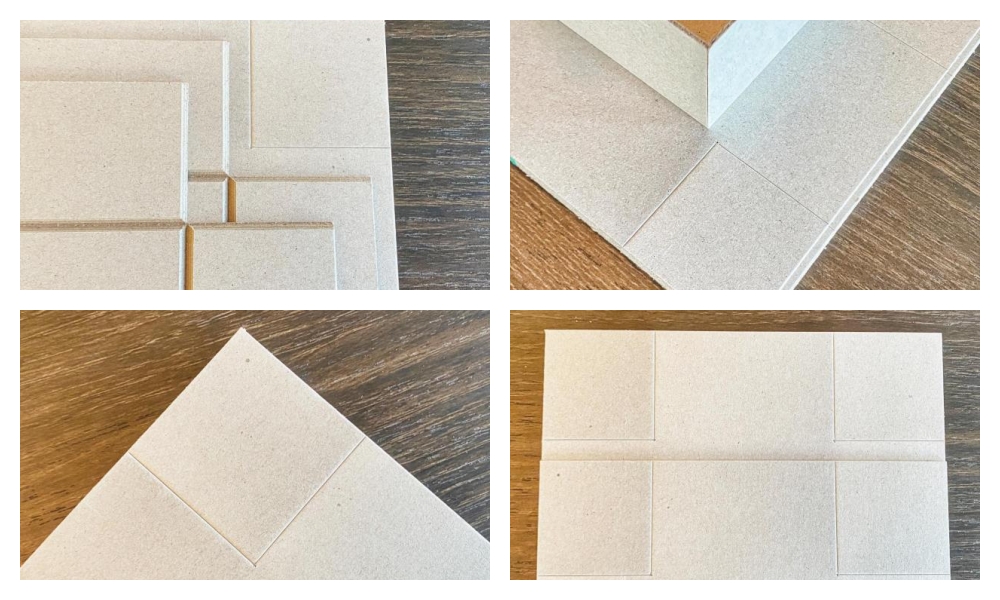

The slit cardboard passes through the conveyor belt and is transported to the first cardboard cutting machine after deflection correction to complete the cardboard cutting in one direction.

After completing the secant line in the first direction, it is conveyed through a 90-degree rotation of the conveyor belt, and then transported into the second cardboard line secant machine after deviation correction to complete the cardboard line secant line in the other direction.

After the two-way secant line of the cardboard is completed, it is transported into the Tic-Tac-toe slotting machine through the conveyor belt, and then the slotting and chamfering of the cardboard is completed through the Tic-Tac-toe slotting machine, and the finished product is output.

Feature:

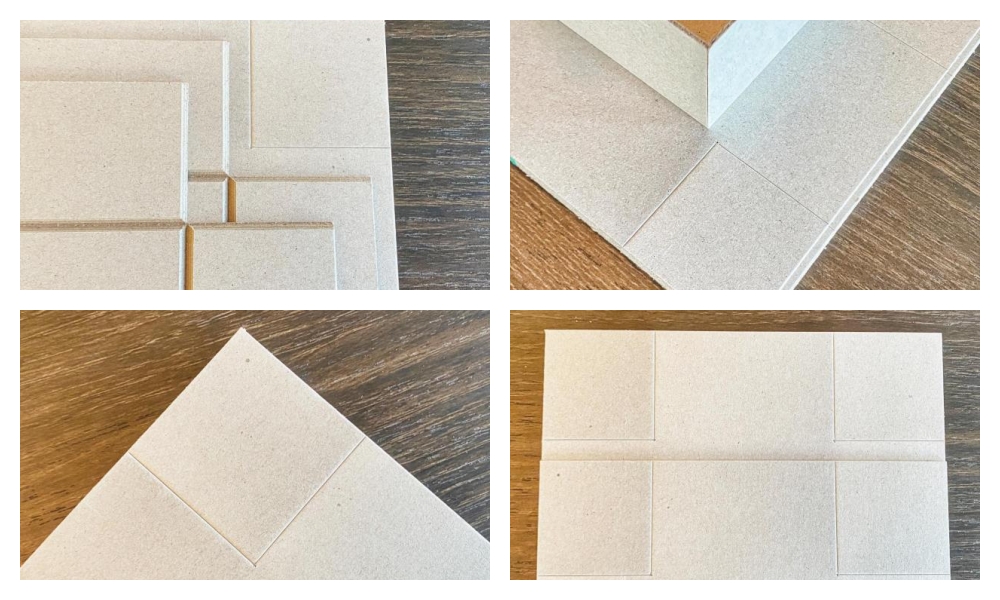

1、Use the traditional mold cutting of the cardboard to change to the method of a servo round knife cut

2、The length of the cutting line is digital adjustment, the operation is simple and easy to use, and there is no need to operate the experience

3、Cutting line vertical and horizontal lines complete completion of sexual completion

4、Cut the cardboard, cut lines, and slots to complete the production, eliminating the intermediate handling link, which greatly reduces labor.

Board half slitting machine | |

| Secant length | 10-120mm |

| Secant length accuracy | ±0.5mm |

| Speed | 80-180Pcs/min |

| Secant balance accuracy | ±0.1mm (same as slotting machine accuracy) |

| Minimum cardboard | 130×130mm |

| Maximum cardboard | 600×600mm |

| Machine size (length*width*height) | 2860×2850×1360mm |

Board grooving machine | |

| Minimum cardboard | 130×130mm |

| Minimum cardboard | 650×650mm |

| Secant length accuracy | ±0.1-0.2mm |

Grooving degree | 80-140 |

| thickness | 1-4mm |

Number of knives per row | 4 |

| Speed | 50-80meter/min OR130piece/min(300*300mm) |

| Machine size (length*width*height) | 4000×2300×1520mm |

| Configuration | Brand Model | Origin |

| sensor | Omron | JAPAN |

| low-voltage apparatus | EATON | USA |

| button switch | EATON | USA |

| photoelectric sensor | BANNER | USA |

| gear motor | TUNGLEE | TAIWAN |

Automatic Grooving Machine and Corner removal for Rigid box(R22A)

The slit cardboard passes through the conveyor belt and is transported to the first cardboard cutting machine after deflection correction to complete the cardboard cutting in one direction.

After completing the secant line in the first direction, it is conveyed through a 90-degree rotation of the conveyor belt, and then transported into the second cardboard line secant machine after deviation correction to complete the cardboard line secant line in the other direction.

After the two-way secant line of the cardboard is completed, it is transported into the Tic-Tac-toe slotting machine through the conveyor belt, and then the slotting and chamfering of the cardboard is completed through the Tic-Tac-toe slotting machine, and the finished product is output.

Feature:

1、Use the traditional mold cutting of the cardboard to change to the method of a servo round knife cut

2、The length of the cutting line is digital adjustment, the operation is simple and easy to use, and there is no need to operate the experience

3、Cutting line vertical and horizontal lines complete completion of sexual completion

4、Cut the cardboard, cut lines, and slots to complete the production, eliminating the intermediate handling link, which greatly reduces labor.

Board half slitting machine | |

| Secant length | 10-120mm |

| Secant length accuracy | ±0.5mm |

| Speed | 80-180Pcs/min |

| Secant balance accuracy | ±0.1mm (same as slotting machine accuracy) |

| Minimum cardboard | 130×130mm |

| Maximum cardboard | 600×600mm |

| Machine size (length*width*height) | 2860×2850×1360mm |

Board grooving machine | |

| Minimum cardboard | 130×130mm |

| Minimum cardboard | 650×650mm |

| Secant length accuracy | ±0.1-0.2mm |

Grooving degree | 80-140 |

| thickness | 1-4mm |

Number of knives per row | 4 |

| Speed | 50-80meter/min OR130piece/min(300*300mm) |

| Machine size (length*width*height) | 4000×2300×1520mm |

| Configuration | Brand Model | Origin |

| sensor | Omron | JAPAN |

| low-voltage apparatus | EATON | USA |

| button switch | EATON | USA |

| photoelectric sensor | BANNER | USA |

| gear motor | TUNGLEE | TAIWAN |

Sign up for our Zetor newsletter

Business Tel: +86-577-66887790

Fax: +86-577-65615260

E-mail: Master@cn-koten.com

Whasapp/Wechat/Mobile: +86-13958895259

Add:Room 402, Unit One, No.5 Building, North Sunshine Road, Anyang Street, Ruian City, Wenzhou, Zhejiang Province, China. ZIP. 325200