SBR-330

Koten

SBR-330

Negotiate

One set

T/T, L/C At Sight

30 sets/month

By strong sea worthy package

Within 30 days after receipt of the deposit.

China

4698

| Availability: | |

|---|---|

| Quantity: | |

This machine is designed to manufacture square bottom paper bags from paper roll in blank or printed. Side gluing, tube forming, cutting, bottom creasing, bottom gluing, bottom forming and final product out feed can be completed within one time by this machine. It is ideal equipment for making paper bag for foodstuff bag, shopping bag and so on. Controlled by PLC system, equipped with in-touch screen and servo motor for bag length control, this machine can produce different size paper bag.

1.Adjustable roll to square bottom bag making machine

2.Introduce In-touch screen human-machine interface, easy for correction and fine adjustment. Alarm and working status can be displayed in screen on-line, easy for operation and maintenance.

3.Equipped with PLC for centralized control system and SICK photocell for correction, tracking the printed material accurately, minimize the adjustment and preset time, increase the production efficiency.

4.Human oriented security protection, whole housing design, ensure the safety of operator.

5.Physiosis roller hydraulic material loading system with chuck, hydraulic up/down system

6.Automatic constant tension control for unwinding, EPC web guider system, motor for material feeding with inverter, minimize the adjustment time for web alignment.

7.High speed oriented design ensure successful of production: within the suitable paper range, production capacity can reach 150~180pcs/min, even higher,which increases the unit production capacity and gets higher profit.

8.Original SCHNEIDER electric system, ensure better stability and reliability; perfect after sale service, trouble free for customer.

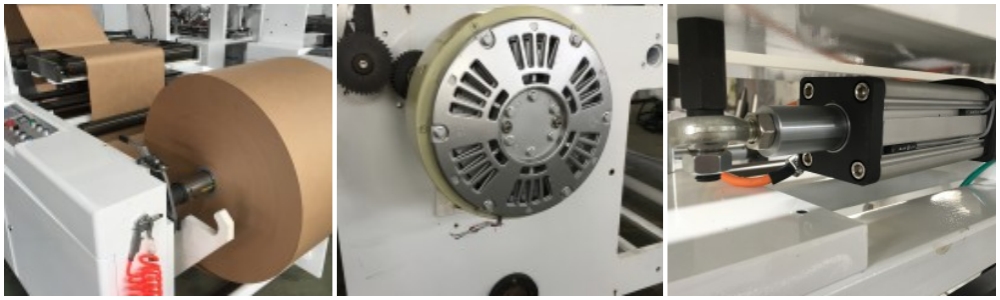

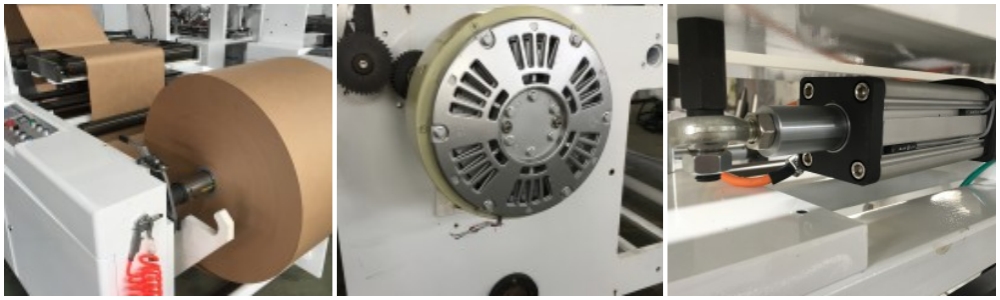

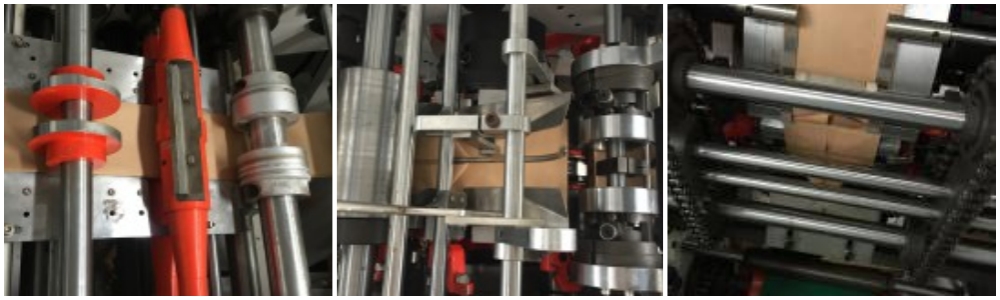

Unwinding Section

(1) Separated single unwind rollstand with hydraulic lift device.

(2) Physiosis roller for paper roll loading, the load arms are driven by two hydraulic cylinders separately, can be adjusted freely.

(3) Magnetic powder brake and constant auto tension control for unwinding tension control.

(4) EPC (electronic program control ) web guide system for material alignment.

Material In-feed and side gluing Section

(1) Separated Material In-feed section

(2) using automatic side glue system, (by air pump), no need add glue by hand.The automatic spray glue, the glue spray will not be interrupt when high speed or low speed, convenient adjustment capacity, glue spray stable .high pressure can save glue, easy and simple to use without cleaning, saving cleaning and saving glue.

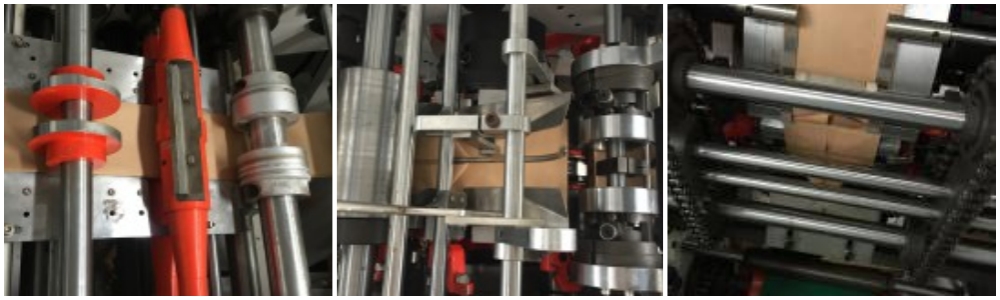

Tube Forming Section

(1) Whole unit tube forming frame

(2) Forming Mould Support Design, Adjustable Former Support for Precise Former Alignment, Adjustable Pressing Wheel

Bottom Forming Section

(1) Material feeding by INDEPENDENT SERVO Draw roll Drive System, Photo Cell System for Running Preprinted Materials (No Change gears)

(2) Rotary Serrated Cutoff with Elliptical Gears

(3) Adjustable Bottom Score Device, can adjust the bag bottom size,

(4) Bottom Opening Cylinder with Split Cam for Full Range Stretch Adjustment

(5) Multi Layer Bottom Forming Drum, Center Grippers, Second Tuck Clamps, and Drum Fingers are adjustable for ease of changeover.

(6) Bottom Glue Applicator with Pneumatic Cylinder for engagement

(7) Bottom Impressing Roller with up/down Feature for Easy

Bottom glue system

Using automatic suck glue by air pump from glue tank,when glue less than sensor,the air pump will working add the glue automatic .reduce working time and Clean.

Bag Delivery Section

(1) Side Table Delivery with Belt for easy operation

(2) Rubber impress roller for Bag Shape Fixation

Control Section

(1) PLC centralized control for whole machine.

(2) Human-machine Interface: Touch Screen Operator Control. Easy to change Machine Settings & Monitoring.

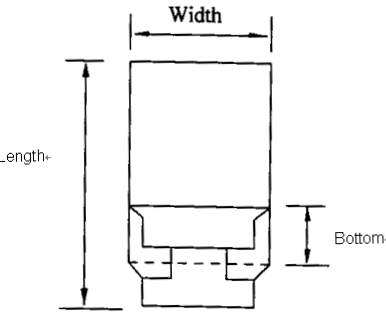

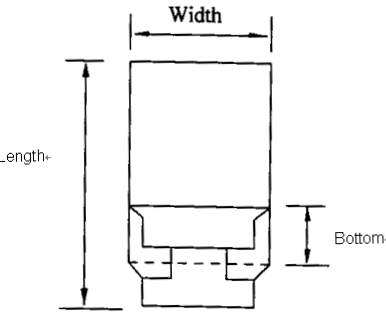

Model | SBR-330 |

Width of Paper roll | 320-930 mm |

Width of Bag | 150-330 mm |

Width of Bag Bottom | 60-160 mm |

Paper weight | 60-160GSM |

Max. Diameter of Paper Roll | ф1500 mm |

Internal Diameter of Roll Core | ф76 mm |

Max.Speed | 200 pcs/min |

Total Power | 15 KW |

Weight of Machine | Approx 6500 kg |

| Overall Dimension | L 8600 mm × W 2500 mm × H 1800 mm |

NAME | BRAND | ORIGINAL |

Bearing | NSK | Japan |

Low Voltage Components | SCHNEIDER | France |

photocell for correction | SICK | Germany |

Servo Motor | Inovance | China |

Electric equipments | SCHNEIDER | France |

This machine is designed to manufacture square bottom paper bags from paper roll in blank or printed. Side gluing, tube forming, cutting, bottom creasing, bottom gluing, bottom forming and final product out feed can be completed within one time by this machine. It is ideal equipment for making paper bag for foodstuff bag, shopping bag and so on. Controlled by PLC system, equipped with in-touch screen and servo motor for bag length control, this machine can produce different size paper bag.

1.Adjustable roll to square bottom bag making machine

2.Introduce In-touch screen human-machine interface, easy for correction and fine adjustment. Alarm and working status can be displayed in screen on-line, easy for operation and maintenance.

3.Equipped with PLC for centralized control system and SICK photocell for correction, tracking the printed material accurately, minimize the adjustment and preset time, increase the production efficiency.

4.Human oriented security protection, whole housing design, ensure the safety of operator.

5.Physiosis roller hydraulic material loading system with chuck, hydraulic up/down system

6.Automatic constant tension control for unwinding, EPC web guider system, motor for material feeding with inverter, minimize the adjustment time for web alignment.

7.High speed oriented design ensure successful of production: within the suitable paper range, production capacity can reach 150~180pcs/min, even higher,which increases the unit production capacity and gets higher profit.

8.Original SCHNEIDER electric system, ensure better stability and reliability; perfect after sale service, trouble free for customer.

Unwinding Section

(1) Separated single unwind rollstand with hydraulic lift device.

(2) Physiosis roller for paper roll loading, the load arms are driven by two hydraulic cylinders separately, can be adjusted freely.

(3) Magnetic powder brake and constant auto tension control for unwinding tension control.

(4) EPC (electronic program control ) web guide system for material alignment.

Material In-feed and side gluing Section

(1) Separated Material In-feed section

(2) using automatic side glue system, (by air pump), no need add glue by hand.The automatic spray glue, the glue spray will not be interrupt when high speed or low speed, convenient adjustment capacity, glue spray stable .high pressure can save glue, easy and simple to use without cleaning, saving cleaning and saving glue.

Tube Forming Section

(1) Whole unit tube forming frame

(2) Forming Mould Support Design, Adjustable Former Support for Precise Former Alignment, Adjustable Pressing Wheel

Bottom Forming Section

(1) Material feeding by INDEPENDENT SERVO Draw roll Drive System, Photo Cell System for Running Preprinted Materials (No Change gears)

(2) Rotary Serrated Cutoff with Elliptical Gears

(3) Adjustable Bottom Score Device, can adjust the bag bottom size,

(4) Bottom Opening Cylinder with Split Cam for Full Range Stretch Adjustment

(5) Multi Layer Bottom Forming Drum, Center Grippers, Second Tuck Clamps, and Drum Fingers are adjustable for ease of changeover.

(6) Bottom Glue Applicator with Pneumatic Cylinder for engagement

(7) Bottom Impressing Roller with up/down Feature for Easy

Bottom glue system

Using automatic suck glue by air pump from glue tank,when glue less than sensor,the air pump will working add the glue automatic .reduce working time and Clean.

Bag Delivery Section

(1) Side Table Delivery with Belt for easy operation

(2) Rubber impress roller for Bag Shape Fixation

Control Section

(1) PLC centralized control for whole machine.

(2) Human-machine Interface: Touch Screen Operator Control. Easy to change Machine Settings & Monitoring.

Model | SBR-330 |

Width of Paper roll | 320-930 mm |

Width of Bag | 150-330 mm |

Width of Bag Bottom | 60-160 mm |

Paper weight | 60-160GSM |

Max. Diameter of Paper Roll | ф1500 mm |

Internal Diameter of Roll Core | ф76 mm |

Max.Speed | 200 pcs/min |

Total Power | 15 KW |

Weight of Machine | Approx 6500 kg |

| Overall Dimension | L 8600 mm × W 2500 mm × H 1800 mm |

NAME | BRAND | ORIGINAL |

Bearing | NSK | Japan |

Low Voltage Components | SCHNEIDER | France |

photocell for correction | SICK | Germany |

Servo Motor | Inovance | China |

Electric equipments | SCHNEIDER | France |

Sign up for our Zetor newsletter

Business Tel: +86-577-66887790

Fax: +86-577-65615260

E-mail: Master@cn-koten.com

Whasapp/Wechat/Mobile: +86-13958895259

Add:Room 402, Unit One, No.5 Building, North Sunshine Road, Anyang Street, Ruian City, Wenzhou, Zhejiang Province, China. ZIP. 325200