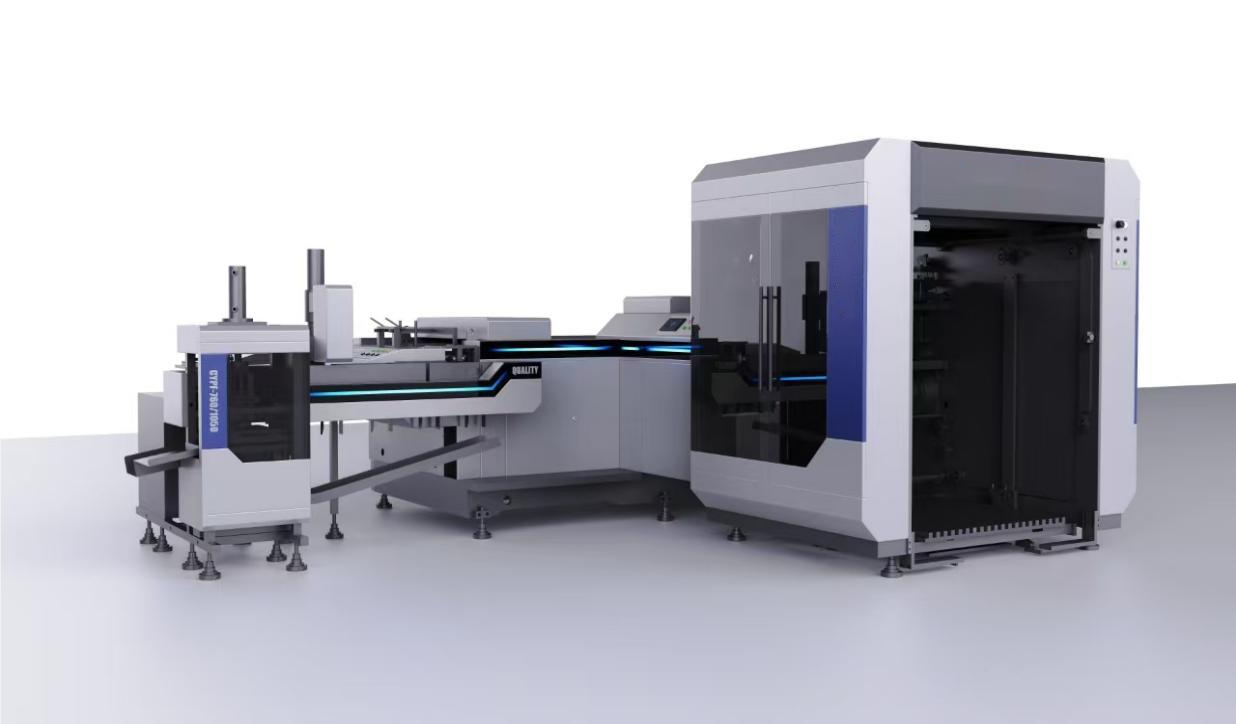

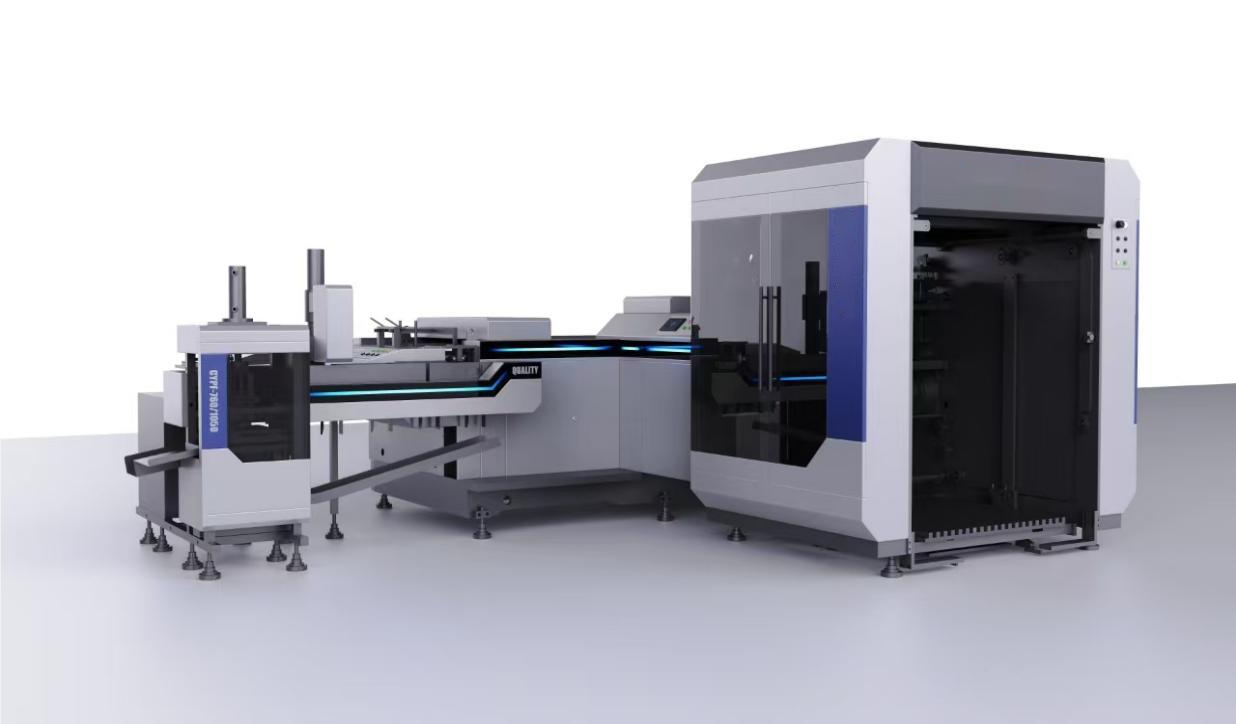

KTKPJ-1050

Koten

KTKPJ-1050

Negotiate

1

T/T, L/C At Sight

30 sets/month

By strong sea worthy package

Within 45 days after receipt of the deposit.

China

3724

| Availability: | |

|---|---|

| Quantity: | |

Automatic Card Punching and Sorting Machine

The CYKPJ-1050 automatic card sorting machine is a new generation of product developed by our company based on market demands, integrating the advantages of various manufacturers and drawing on our company's over twenty years of practical experience.

It is an ideal multi-purpose device for the production of game cards, anime cards, blind box opening, playing cards, etc.

This machine features high performance and high efficiency. It can meet the professional demands for surface finishing of printed materials and bring the quality level of your company's card products to a new height. It not only saves human and material resources, but also greatly shortens the production cycle.

Feature

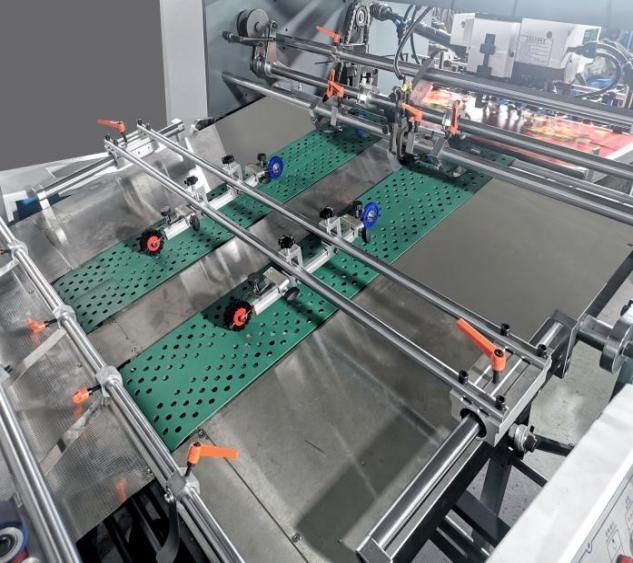

1. This machine adopts a servo-driven feeder for paper feeding, effectively enhancing stability and service life.

2. When the paper is not aligned with the tension gauge on the board, the board

can be adjusted left and right by a servo motor.

3. The paper feeding machine conveyor table uses two PU conveyor belts. The

200MM wide belts are equipped with suction at the bottom, ensuring smooth

paper feeding.

4. The conveyor platform plate is made of stainless steel checkered plate, effectively preventing the static electricity on the surface of the paper from causing it to run skewed or double sheets.

5. This machine adopts wireless networking. If there are any issues with the program, it can be remotely controlled and resolved without any worries

6. The entire machine is equipped with 6 servo linkages, and each power head can be fine-tuned.

Model:KTKPJ-1050 | |

Max.paper sheet size | 1050mm×710mm |

Min. paper sheet size | 310mm×290mm |

Paper thickness | 150-1200g/m |

Laminating speed | 2200-3000 paper/hour |

Production power | 8kw |

Maximum production card size | 150×155mm |

Minimum production card size | 52×52mm |

Total Power | 12kw |

Overall Dimensions(L*W*H) | 5020×5230×2000(mm) |

Weight | 4500kg |

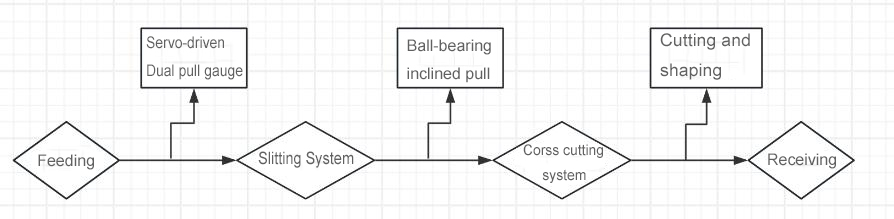

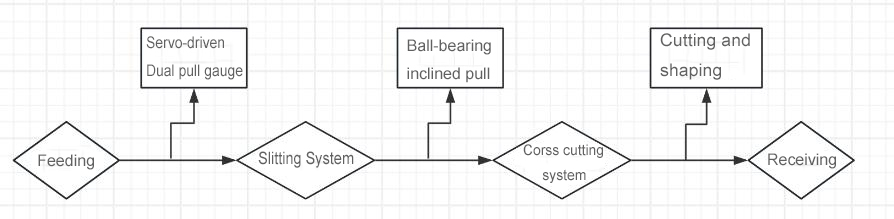

1.Automatic paper feeder This machine adopts the fourth-generation feeder,a servo driven feeder,replacingthe traditional transmission shaft mechanism, effectively enhancing the smoothness of transmission and service life.The operation process is smooth and stable, saving time and increasing production capacity.

The paper conveying platform adopts a servo drive structure to ensure smooth high-speed paper feeding. Ensure accuracy under uniform operation. Under the conditions of acceleration and deceleration operation, the automatic paper feeder has restrictions on the maximum and minimum paper sizes (subject to the technical parameters). In addition to the paper width being restricted by the format, the maximum and minimum paper lengths

should be limited in a ratio of 3:1.

2. Double tension gauge system This machine adopts a double tension gauge system, which can achieve forward and reverse tension, ensuring the stability and accuracy of the operation process

3. Longitudinal cutting unit

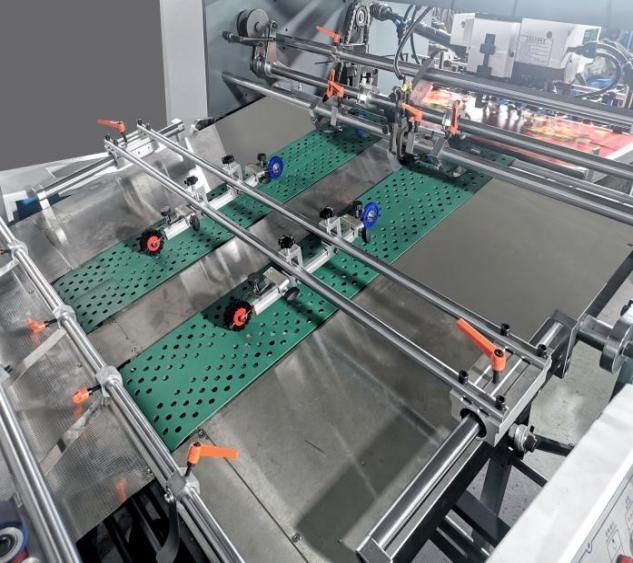

4.Ball inclined pull system This machine uses a steel rod inclined in coordination with steel balls to convey the paper close to the baffle. There will be no deviation during cross cutting, and the baffle can be fine tuned forward and backward.

5. Cross-cutting unit The rubber rollers in Group 1 are fixed, those in Group 2 are slitted up and down, those in group 3 are pulled, and those in group 4 are broken or conveyed.

6. Card output port Group 1 is fixed, Group 2 is pulled or broken, and Group 3 is output

7.Transposition Controlled by a servo motor, the grid movement can be set to move once after each card is played or once after two cards are played (stacking two decks of cards), which can increase the speed and reduce the number of stamping operations.

8. Hydraulic system The displacement cylinder pushes the card once, and the stamping system completes it once. The proximity switch can adjust the stroke of the oil cylinder core shaft according to the height of the card to achieve the best working state. The displacement cylinder has a photoelectric sensor back and forth. When it is not aligned or the photoelectric sensor is damaged, the machine will alarm. Check and handle it properly before resuming work. One stamping operation is completed, and the two 90 cylinders complete three operations.

Automatic Card Punching and Sorting Machine

The CYKPJ-1050 automatic card sorting machine is a new generation of product developed by our company based on market demands, integrating the advantages of various manufacturers and drawing on our company's over twenty years of practical experience.

It is an ideal multi-purpose device for the production of game cards, anime cards, blind box opening, playing cards, etc.

This machine features high performance and high efficiency. It can meet the professional demands for surface finishing of printed materials and bring the quality level of your company's card products to a new height. It not only saves human and material resources, but also greatly shortens the production cycle.

Feature

1. This machine adopts a servo-driven feeder for paper feeding, effectively enhancing stability and service life.

2. When the paper is not aligned with the tension gauge on the board, the board

can be adjusted left and right by a servo motor.

3. The paper feeding machine conveyor table uses two PU conveyor belts. The

200MM wide belts are equipped with suction at the bottom, ensuring smooth

paper feeding.

4. The conveyor platform plate is made of stainless steel checkered plate, effectively preventing the static electricity on the surface of the paper from causing it to run skewed or double sheets.

5. This machine adopts wireless networking. If there are any issues with the program, it can be remotely controlled and resolved without any worries

6. The entire machine is equipped with 6 servo linkages, and each power head can be fine-tuned.

Model:KTKPJ-1050 | |

Max.paper sheet size | 1050mm×710mm |

Min. paper sheet size | 310mm×290mm |

Paper thickness | 150-1200g/m |

Laminating speed | 2200-3000 paper/hour |

Production power | 8kw |

Maximum production card size | 150×155mm |

Minimum production card size | 52×52mm |

Total Power | 12kw |

Overall Dimensions(L*W*H) | 5020×5230×2000(mm) |

Weight | 4500kg |

1.Automatic paper feeder This machine adopts the fourth-generation feeder,a servo driven feeder,replacingthe traditional transmission shaft mechanism, effectively enhancing the smoothness of transmission and service life.The operation process is smooth and stable, saving time and increasing production capacity.

The paper conveying platform adopts a servo drive structure to ensure smooth high-speed paper feeding. Ensure accuracy under uniform operation. Under the conditions of acceleration and deceleration operation, the automatic paper feeder has restrictions on the maximum and minimum paper sizes (subject to the technical parameters). In addition to the paper width being restricted by the format, the maximum and minimum paper lengths

should be limited in a ratio of 3:1.

2. Double tension gauge system This machine adopts a double tension gauge system, which can achieve forward and reverse tension, ensuring the stability and accuracy of the operation process

3. Longitudinal cutting unit

4.Ball inclined pull system This machine uses a steel rod inclined in coordination with steel balls to convey the paper close to the baffle. There will be no deviation during cross cutting, and the baffle can be fine tuned forward and backward.

5. Cross-cutting unit The rubber rollers in Group 1 are fixed, those in Group 2 are slitted up and down, those in group 3 are pulled, and those in group 4 are broken or conveyed.

6. Card output port Group 1 is fixed, Group 2 is pulled or broken, and Group 3 is output

7.Transposition Controlled by a servo motor, the grid movement can be set to move once after each card is played or once after two cards are played (stacking two decks of cards), which can increase the speed and reduce the number of stamping operations.

8. Hydraulic system The displacement cylinder pushes the card once, and the stamping system completes it once. The proximity switch can adjust the stroke of the oil cylinder core shaft according to the height of the card to achieve the best working state. The displacement cylinder has a photoelectric sensor back and forth. When it is not aligned or the photoelectric sensor is damaged, the machine will alarm. Check and handle it properly before resuming work. One stamping operation is completed, and the two 90 cylinders complete three operations.

Sign up for our Zetor newsletter

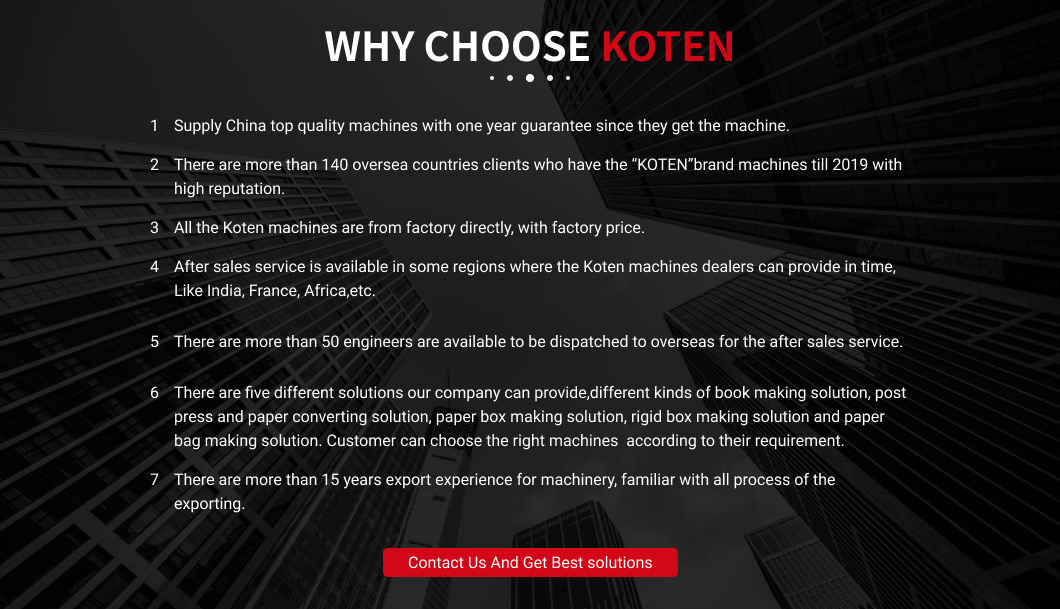

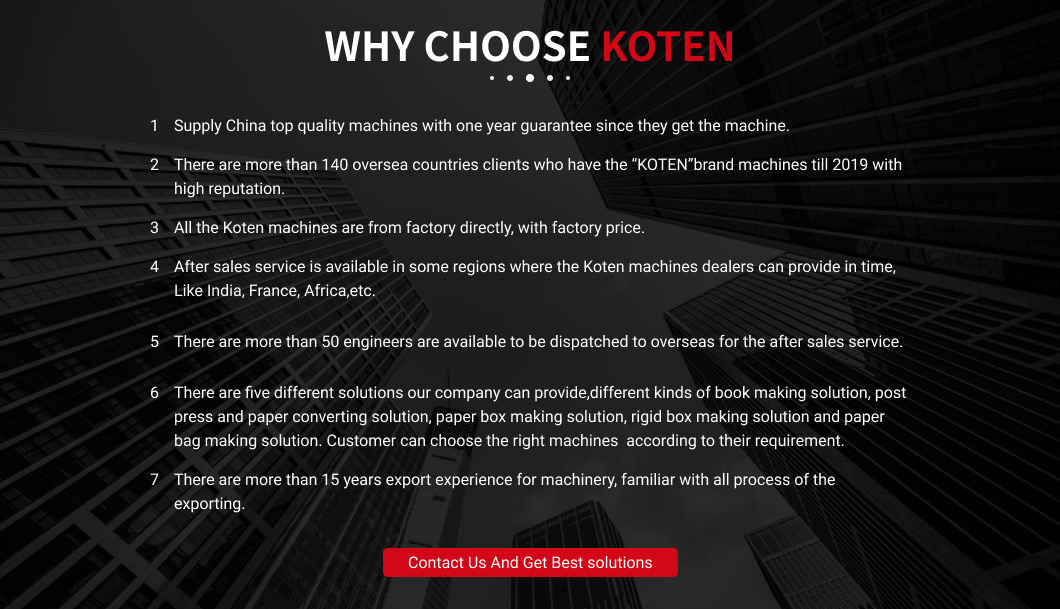

Business Tel: +86-577-66887790

Fax: +86-577-65615260

E-mail: Master@cn-koten.com

Whasapp/Wechat/Mobile: +86-13958895259

Add:Room 402, Unit One, No.5 Building, North Sunshine Road, Anyang Street, Ruian City, Wenzhou, Zhejiang Province, China. ZIP. 325200