AEM-1300/1500/1650S(Q)

Koten

AEM-1300/1500/1650S(Q)

Negotiate

1set

T/T,L/C.

30sets/month

By strong seaworthy wooden cases.

Within 60 days after get the deposit.

China

7484

| Availability: | |

|---|---|

| Quantity: | |

AEM-S(Q) Automatic platen die cutting machine is used for die cutting various paper, paperboard, corrugated board, with function of die cutting, creasing and embossing.

Safety, Energy Saving, Efficient

1. Platen press is driven by Taiwan TECO main motor with Panasonic inverter; the running of complete machine is controlled by PLC centralized controlling system which can automatically examine the working status and test unusual status as well as record the working condition. According to the Europe Safety Standard, we design reasonably to make the operability and safety perfect combination.

2. Advanced alarm system of starting up will remind operator to leave the unsafe area. Automatically detecting whole process, if malfunction, non-paper or paper stuck, the pneumatic clutch will separate and stop automatically which reduce the waste of paper, protect the staff and equipment.

3. Elaborate pre-stacked device and paper feeding & delivery non-stop devices reduce the time of stacking, improve the efficiency of machine and increase your income.

4. Selected European, Japanese, Taiwan electrical and pneumatic components improve the stability of the machine and reduce the frequency of inanimateness.

5. Mainframe and base adopt high strength spheroidal graphite iron QT500-7 which is accurately processed by numerical control center, guarantee the machine run stably in long time when bearing large pressure. The cores of the platen press machine such as crankshaft, worm gear, are all imported high-class alloy steel, which are processed by quenching and high temperature tempering with a long working life.

6. Lubrication system for core parts is equipped with display device for oil pressure and alarming device for insufficient pressure of oil and air.

7. Supply long-term and complete technical training as well as prompt free maintains for one year, guarantee that our clients can fully master the production technology of our equipment. Our machine is with Perfect design, accurate installation, high stability, high security, low noise.

Paper Feeding Section: feeder and conveyor table

1.Manual-automatic dual-use feeder: some papers cannot be fed by feeder head because of the bad quality(out of shape), the operator can feed them by hand while lifting the head up.

2.Precision feeder head(Becker vacuum pump): suitable for both paperboard and corrugated board. The angle and height of nozzles can be adjusted to suit the different shapes of paper.

3. Electra-mechanical double-sheet detector.

4. Conveyer table with anti-wore PU press rollers and the brush wheels guarantees high feeding accuracy of paper, the conveyer belt can be adjusted nonstop.

5. Double-usage side lay (pull and push) and front lay guarantee accuracy of the sheet position.

6. Skew paper and accumulated paper detection function and auto stop function: when the sensors detect the paper is skewed or accumulated before being delivered to platen press section, machine will stop.

7. Non-stop paper feeding structure and guide rail type pre-packed pallet improve the efficiency largely.

8. Various fine-adjustment devices is easy for operator to adjust the machine, ensures the paper can be delivered accurately.

Platen Press Section

1.Main body adopts high-strength ductile iron QT500 with special casting process. The Ni-Cr-Mo Alloy crankshaft with special craft process treatment and super wear-resistant worm and gear.

2. High pressure automatic oil motor with filter and cooling fan recycles the oil to lubricate the main transmission parts(crankshaft, worm and gear). And the auto oil pump lubricates all of the necessary parts(gear, chains, etc.)

3. Big flywheel with the pneumatic clutch guarantees high precision when machine is high speed running.

4.Human-friendly design for die and liner plate(Manganese Steel)changing. Die frame can be overturned and locked pneumatically.

5. High-precision cam indexer to control the gripper bars to deliver paper in accurate position.

6. High-strength Ti-Al alloy grippers and wear-resisting chains for gripper bar

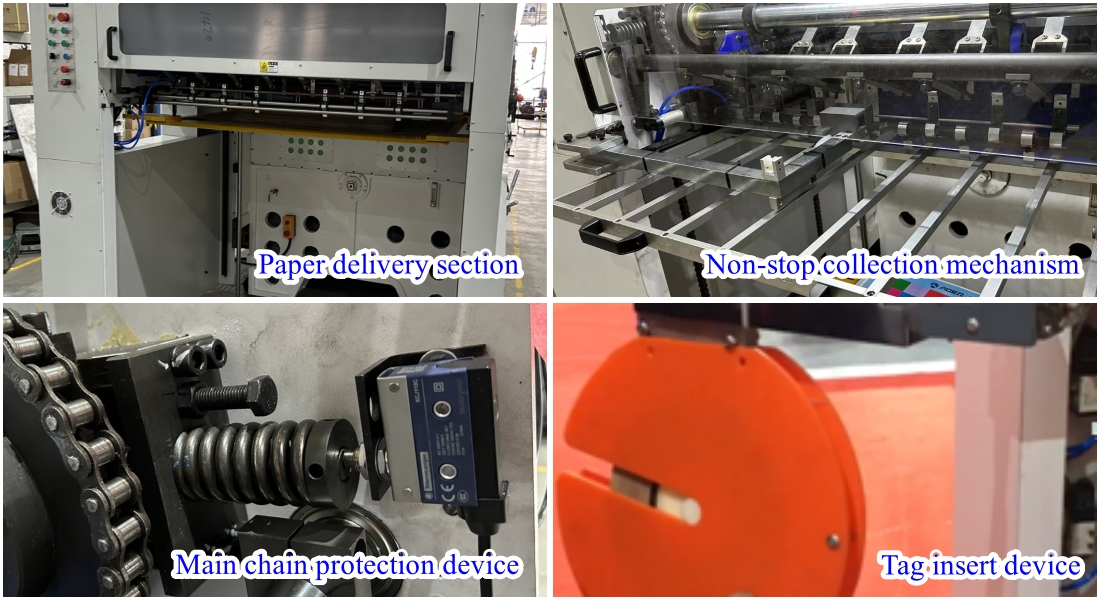

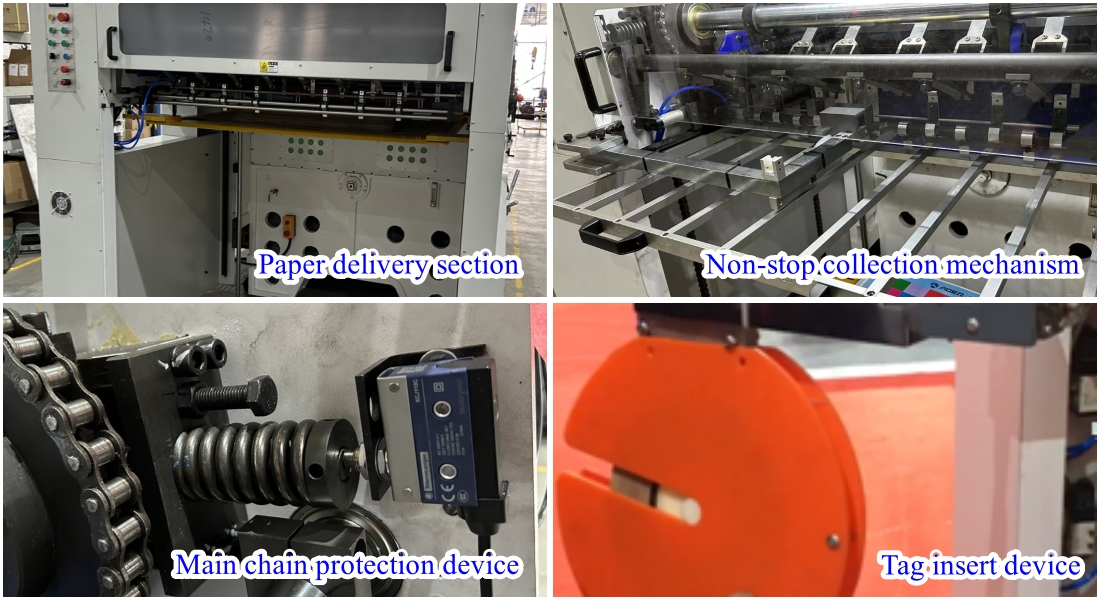

Paper Delivery Section

1.Automatic aligning device, double side blowers and hair brush guarantee paper pile in good order, no matter the paper is thick or thin.

2.Overrun-prevention device: The sheet is moved upwards with the gripper bar, the detection sensor will be initiated and machine will stop.

3.Gripper chains protection device: sensors are connected to the main chains to monitor the tightness of the chains. When it is detected to be loose, the machine will be stopped.

4.The non-stop paper delivery device.

5.Tag insert device(1 set) to record the sheets quantity.

Electrical box and control system

1.Interface controls are integrated, and numerous electrical switch controls are set in operation screen which is easy operation and easy understanding.

2.PLC centralized controlling system can automatically examine the working status and test unusual status as well as record the working condition.

3. Problem diagnosis function on touch screen, if any problems occur, you can check touch screen to find it.

4. Chinese, English or other any language(optional) on touch screen

5.Electrical components and electrical circuit are in accord with Europe American safety standard.

Heating plate for plastic sheet(OPTIONAL)

For die cutting the plastic sheet, like PVC, PP, PET sheet

1.Separate setting temperature for independent heating zones, thermostatic control.

2.Heating plate is made by heat-resisting and high strength casting iron RTCr0.8.

Stripper Section(OPTIONAL)

1.Stripper is composed of three frames (upper, middle, and bottom frame) which can be pulled out for installation of pins.

2.Stripper bar with pins or male-female plate for waste stripping.

| Model | AEM-1300S | AEM-1500S | AEM-1650S |

| Max. Sheet Size | 1320×980 mm | 1500×1100 mm | 1670×1210 mm |

| Min. Sheet Size | 470×370 mm | 470×440 mm | 520×460 mm |

| Feeding Pile Height | 1400mm | 1300mm | 1500mm |

| Delivery Pile Height | 1200mm | 1200mm | 1300mm |

| Max. Die-Cutting Size | 1300×970 mm | 1490×1090 mm | 1650×1200 mm |

| Inner Chase Size | 1330×992 mm | 1540×1100 mm | 1660×1215 mm |

| Die Cutting Plate Size | 1320×982 mm | 1500×1100 mm | 1680×1186 mm |

| Cutting Rule Height | 23.8mm | 23.8mm | 23.8mm |

| Cutting Plate Thickness | 7mm | 7mm | 7mm |

| Stock Range | Paperboard:0.25~2 mm | ||

| Corrugated paper:<8 mm | |||

| Plastic sheet: 0.2~1 mm(heating plate is optional) | |||

| Die-Cutting Accuracy | ≤±0.2 mm | ≤±0.25 mm | ≤±0.25 mm |

| Max. Die-Cutting Pressure | 280 T | 300 T | 300 T |

| Max. Machine Speed | 5000 S/H | 4800 S/H | 4500 S/H |

| Min Gripper Margin | 7mm | 7mm | 7mm |

| Air Supply | 0.6-0.7Mpa, 0.36m³/Min | ||

| Power Requirement | 3 phases 380V 50HZ | ||

| Main Motor Power | 11KW | 15KW | 15KW |

| Heating area power(if for plastic cutting, optional) | 24 KW (12 heating zone, each zone is 2kw) | 24 KW (12 heating zone, each zone is 2kw) | 24 KW (12 heating zone, each zone is 2kw) |

| Total Power(without heating) | 17.8kw | 22KW | 22KW |

| Total Machine Weight AEM-S | 18 T | 20 T | 23 T |

| Total Machine Weight AEM-SQ | 20.5 T | 22.5 T | 25 T |

| Overall Dimension AEM-S | 6000(+1800)×2350(+1900)×2350mm | 6500(+2000)×2600(+2200)×2850 mm | 6900(+2300)×3000(+2300)×2550 mm |

| Overall Dimension AEM-SQ | 7200(+1800)×2350(+1900)×2350mm | 7900(+2000)×2600(+2200)×2850 mm | 8400(+2300)×3000(+2300)× 2550 mm |

| Name | Materials (Brand)/Origin | Name | Materials (Brand)/Origin |

| Main frame structure | QT500-7 spheroidal graphite cast iron | PLC and touch screen | Fatek, Taiwan |

| Platen press base-plate | 75Cr1 alloy steel | Touch Screen | WECON, Taiwan |

| Crankshaft | Cr-Ni-Mo alloy steel,Taiwan | Main motor | Tech, Taiwan |

| Pneumatic electromagnetic valve | Airtac, Taiwan | Gear motor | CPG/Dongli, Taiwan |

| Gripper bar | Ti-Al alloy, Taiwan | Vacuum pump | Becker, Germany |

| Gripper teeth | Manganese steel, Taiwan | Inverter | Panasonic, Japan |

| Cam indexing unit | Handex, Taiwan | Encoder | Omron, Japan |

| Main transmission chain | TYC, Taiwan | Fiber optic sensor | Panasonic, Japan |

| Main key bearing | NSK,Japan | photoelectric sensor | Panasonic, Japan |

| AC contactor | Schneider, France | Relay | Schneider, France |

| Breaker | Schneider, France | Button | Schneider, France |

AEM-S(Q) Automatic platen die cutting machine is used for die cutting various paper, paperboard, corrugated board, with function of die cutting, creasing and embossing.

Safety, Energy Saving, Efficient

1. Platen press is driven by Taiwan TECO main motor with Panasonic inverter; the running of complete machine is controlled by PLC centralized controlling system which can automatically examine the working status and test unusual status as well as record the working condition. According to the Europe Safety Standard, we design reasonably to make the operability and safety perfect combination.

2. Advanced alarm system of starting up will remind operator to leave the unsafe area. Automatically detecting whole process, if malfunction, non-paper or paper stuck, the pneumatic clutch will separate and stop automatically which reduce the waste of paper, protect the staff and equipment.

3. Elaborate pre-stacked device and paper feeding & delivery non-stop devices reduce the time of stacking, improve the efficiency of machine and increase your income.

4. Selected European, Japanese, Taiwan electrical and pneumatic components improve the stability of the machine and reduce the frequency of inanimateness.

5. Mainframe and base adopt high strength spheroidal graphite iron QT500-7 which is accurately processed by numerical control center, guarantee the machine run stably in long time when bearing large pressure. The cores of the platen press machine such as crankshaft, worm gear, are all imported high-class alloy steel, which are processed by quenching and high temperature tempering with a long working life.

6. Lubrication system for core parts is equipped with display device for oil pressure and alarming device for insufficient pressure of oil and air.

7. Supply long-term and complete technical training as well as prompt free maintains for one year, guarantee that our clients can fully master the production technology of our equipment. Our machine is with Perfect design, accurate installation, high stability, high security, low noise.

Paper Feeding Section: feeder and conveyor table

1.Manual-automatic dual-use feeder: some papers cannot be fed by feeder head because of the bad quality(out of shape), the operator can feed them by hand while lifting the head up.

2.Precision feeder head(Becker vacuum pump): suitable for both paperboard and corrugated board. The angle and height of nozzles can be adjusted to suit the different shapes of paper.

3. Electra-mechanical double-sheet detector.

4. Conveyer table with anti-wore PU press rollers and the brush wheels guarantees high feeding accuracy of paper, the conveyer belt can be adjusted nonstop.

5. Double-usage side lay (pull and push) and front lay guarantee accuracy of the sheet position.

6. Skew paper and accumulated paper detection function and auto stop function: when the sensors detect the paper is skewed or accumulated before being delivered to platen press section, machine will stop.

7. Non-stop paper feeding structure and guide rail type pre-packed pallet improve the efficiency largely.

8. Various fine-adjustment devices is easy for operator to adjust the machine, ensures the paper can be delivered accurately.

Platen Press Section

1.Main body adopts high-strength ductile iron QT500 with special casting process. The Ni-Cr-Mo Alloy crankshaft with special craft process treatment and super wear-resistant worm and gear.

2. High pressure automatic oil motor with filter and cooling fan recycles the oil to lubricate the main transmission parts(crankshaft, worm and gear). And the auto oil pump lubricates all of the necessary parts(gear, chains, etc.)

3. Big flywheel with the pneumatic clutch guarantees high precision when machine is high speed running.

4.Human-friendly design for die and liner plate(Manganese Steel)changing. Die frame can be overturned and locked pneumatically.

5. High-precision cam indexer to control the gripper bars to deliver paper in accurate position.

6. High-strength Ti-Al alloy grippers and wear-resisting chains for gripper bar

Paper Delivery Section

1.Automatic aligning device, double side blowers and hair brush guarantee paper pile in good order, no matter the paper is thick or thin.

2.Overrun-prevention device: The sheet is moved upwards with the gripper bar, the detection sensor will be initiated and machine will stop.

3.Gripper chains protection device: sensors are connected to the main chains to monitor the tightness of the chains. When it is detected to be loose, the machine will be stopped.

4.The non-stop paper delivery device.

5.Tag insert device(1 set) to record the sheets quantity.

Electrical box and control system

1.Interface controls are integrated, and numerous electrical switch controls are set in operation screen which is easy operation and easy understanding.

2.PLC centralized controlling system can automatically examine the working status and test unusual status as well as record the working condition.

3. Problem diagnosis function on touch screen, if any problems occur, you can check touch screen to find it.

4. Chinese, English or other any language(optional) on touch screen

5.Electrical components and electrical circuit are in accord with Europe American safety standard.

Heating plate for plastic sheet(OPTIONAL)

For die cutting the plastic sheet, like PVC, PP, PET sheet

1.Separate setting temperature for independent heating zones, thermostatic control.

2.Heating plate is made by heat-resisting and high strength casting iron RTCr0.8.

Stripper Section(OPTIONAL)

1.Stripper is composed of three frames (upper, middle, and bottom frame) which can be pulled out for installation of pins.

2.Stripper bar with pins or male-female plate for waste stripping.

| Model | AEM-1300S | AEM-1500S | AEM-1650S |

| Max. Sheet Size | 1320×980 mm | 1500×1100 mm | 1670×1210 mm |

| Min. Sheet Size | 470×370 mm | 470×440 mm | 520×460 mm |

| Feeding Pile Height | 1400mm | 1300mm | 1500mm |

| Delivery Pile Height | 1200mm | 1200mm | 1300mm |

| Max. Die-Cutting Size | 1300×970 mm | 1490×1090 mm | 1650×1200 mm |

| Inner Chase Size | 1330×992 mm | 1540×1100 mm | 1660×1215 mm |

| Die Cutting Plate Size | 1320×982 mm | 1500×1100 mm | 1680×1186 mm |

| Cutting Rule Height | 23.8mm | 23.8mm | 23.8mm |

| Cutting Plate Thickness | 7mm | 7mm | 7mm |

| Stock Range | Paperboard:0.25~2 mm | ||

| Corrugated paper:<8 mm | |||

| Plastic sheet: 0.2~1 mm(heating plate is optional) | |||

| Die-Cutting Accuracy | ≤±0.2 mm | ≤±0.25 mm | ≤±0.25 mm |

| Max. Die-Cutting Pressure | 280 T | 300 T | 300 T |

| Max. Machine Speed | 5000 S/H | 4800 S/H | 4500 S/H |

| Min Gripper Margin | 7mm | 7mm | 7mm |

| Air Supply | 0.6-0.7Mpa, 0.36m³/Min | ||

| Power Requirement | 3 phases 380V 50HZ | ||

| Main Motor Power | 11KW | 15KW | 15KW |

| Heating area power(if for plastic cutting, optional) | 24 KW (12 heating zone, each zone is 2kw) | 24 KW (12 heating zone, each zone is 2kw) | 24 KW (12 heating zone, each zone is 2kw) |

| Total Power(without heating) | 17.8kw | 22KW | 22KW |

| Total Machine Weight AEM-S | 18 T | 20 T | 23 T |

| Total Machine Weight AEM-SQ | 20.5 T | 22.5 T | 25 T |

| Overall Dimension AEM-S | 6000(+1800)×2350(+1900)×2350mm | 6500(+2000)×2600(+2200)×2850 mm | 6900(+2300)×3000(+2300)×2550 mm |

| Overall Dimension AEM-SQ | 7200(+1800)×2350(+1900)×2350mm | 7900(+2000)×2600(+2200)×2850 mm | 8400(+2300)×3000(+2300)× 2550 mm |

| Name | Materials (Brand)/Origin | Name | Materials (Brand)/Origin |

| Main frame structure | QT500-7 spheroidal graphite cast iron | PLC and touch screen | Fatek, Taiwan |

| Platen press base-plate | 75Cr1 alloy steel | Touch Screen | WECON, Taiwan |

| Crankshaft | Cr-Ni-Mo alloy steel,Taiwan | Main motor | Tech, Taiwan |

| Pneumatic electromagnetic valve | Airtac, Taiwan | Gear motor | CPG/Dongli, Taiwan |

| Gripper bar | Ti-Al alloy, Taiwan | Vacuum pump | Becker, Germany |

| Gripper teeth | Manganese steel, Taiwan | Inverter | Panasonic, Japan |

| Cam indexing unit | Handex, Taiwan | Encoder | Omron, Japan |

| Main transmission chain | TYC, Taiwan | Fiber optic sensor | Panasonic, Japan |

| Main key bearing | NSK,Japan | photoelectric sensor | Panasonic, Japan |

| AC contactor | Schneider, France | Relay | Schneider, France |

| Breaker | Schneider, France | Button | Schneider, France |

Sign up for our Zetor newsletter

Business Tel: +86-577-66887790

Fax: +86-577-65615260

E-mail: Master@cn-koten.com

Whasapp/Wechat/Mobile: +86-13958895259

Add:Room 402, Unit One, No.5 Building, North Sunshine Road, Anyang Street, Ruian City, Wenzhou, Zhejiang Province, China. ZIP. 325200