DP-A4055

Koten

DP-A4055

Negotiate

1set

T/T,L/C.

30sets/month

By strong seaworthy wooden cases.

Within 60 days after get the deposit.

China

3584

| Availability: | |

|---|---|

| Quantity: | |

Introduction.

Roller Die Cutting machine is to cut the paper with the mould. It can be applied to normal paper, coated paper and cardboard, (the following paper cannot be processed: composite paper (covered with polypropylene) or plastic film). Speed can reach 6000 cycles per hour. It can remove the waste automatically, easy to operate and save time with the efficient work.

1. Operation Console

Both setup and control can be done though the intuitive touch screen. After setting upper and lower die, the system can be set up by simply inputting sheet size and product size. The graphical illustrations on the screen are simple and easy to understand.

2. Feed Section

Vacuum belt feeding enables superior feeding with easy setup and operation. An ultrasonic sensor is used for double feed detection on a wide range of substrates.

3. Transport Section

Sheets are registered by vacuum belt and position is firmly secured with gripper rollers for high quality finish. Servo motor driven gripper rollers ensure the die cut position without effecting processing speed.

4. Die Cutting

Rigid magnetic upper roller and solid lower anvil roller ensure high quality die cutting. Uniquely designed die cutting section enables easy and quick die setting. Both 0.6mm and 0.8mm/0.0236’’ and 0.0315’’ thickness of flexible die plates can be used.

5. Separator

The separator removes the waste from the finished product and delivers it to the waste bin. Air cylinder driven separator pins and sir jets can be used depending on size of the waste.

6. Delivery Section

Finished products are delivered on the motorized conveyor. Intermittent conveyor movement maximizes the continuous operation in a small space. Gap can be adjusted depending on the size of the product for easy handling.

7. Multi-functional system die cutting、kiss cutting creasing、repeat cutting

8. Rotary Die cutting machine (Max.400x550 mm)-Rotary Die-Cutter designed to meet the growing demand.

9. Flexible substrate-Die cut, Crease, Perforation, Silt, Hole punch and round corner in various substrates up to 0.5mm(only for die cutting)thickness for digital and offset printed sheets.

10. One pass processing-Feeding, die cutting and separating are achieved in one pass at a speed of 6,000 cycles per hour.

11. Save the cost of making die-Uniquely designed servo motor controlled ”Repeat Register” feature allows multiple-up applications from single-up die to minimize die cost.

12. Simple and easy operation-Reduces costly labor steps and increases productivity.

A. Sheet Flow.

This section describes the sheet flow from the feed unit through the die cutter and the separator. The separator separates the cut product from the sheet.

DP-4055 Specifications | |||

Sheet feeding system | Vacuum Feed Belts | ||

Sheet Size(before processing) |

Width x Length | Max.400X550mm/15.74X21.65 Min.200X275mm/ 7.88X10.83 | |

Cut product Size The size may be limited depending on shape and sheet weight range. | separator | Max.376X530mm/14.8X20.8 | |

Min.50X80mm/1.97X3.15 | |||

Without separator | Max.384X530mm/15.1X20.8 | ||

Min. Depending on die shape | |||

Processed Material | Normal paper, Coated paper, Cardboard | ||

Material Thickness | 127.9 to 400gsm

0.5mm/0.019 Die cutting:Max.0.5mm/0.019 0.8mm/0.031 (In case of blade height:0.8mm/0.031)

0.3mm/0.001 Die cutting:Max.0.3mm/0.001 0.6mm/0.023 (In case of blade height:0.6mm/0.023)

0.4mm/0.015 Creasing:Max.0.4mm/0.015 0.8mm/0.031 (In case of blade height:0.8mm/0.031) |

Feeder stack Height |

500mm/19.68 |

Die Size Upper Die | Max.400X560mm/15.74X22.04 Min.160X100mm/6.30X3.94 |

Upper Cutting Blade Height |

0.6mm or 0.8mm/0.0236 or 0.0315 |

Production Speed | 6000 个 6000cycles per hour |

Voltage/Frequency | 200-240V,50 / 60Hz Single Phase 200 to 240V,50/60Hz |

Machine Weight | With separator:1200KG Without separator:900KG |

Configuration:

NO. | Configuration | Brand |

| 1. | 10’’ touch screen | AB |

| 2. | Control system | AB |

| 3. | Expansion module | AB |

| 4. | Power module | AB |

| 5. | Communication module | AB |

| 6. | Ending cover | AB |

| 7. | Servo Motor | Panasonnic |

| 8. | Servo driver | AB |

| 9. | Servo cable | AB |

| 10. | Exchange | AB |

| 11. | Communication cable | AB |

| 12. | Encoder | AB |

| 13. | Encoder access module | AB |

| 14. | Transducer | AB |

| 15 | Stepping drive | Kinco |

| 16 | X2 Communication plug | Panasonnic |

| 17. | Stepping motor | Kinco |

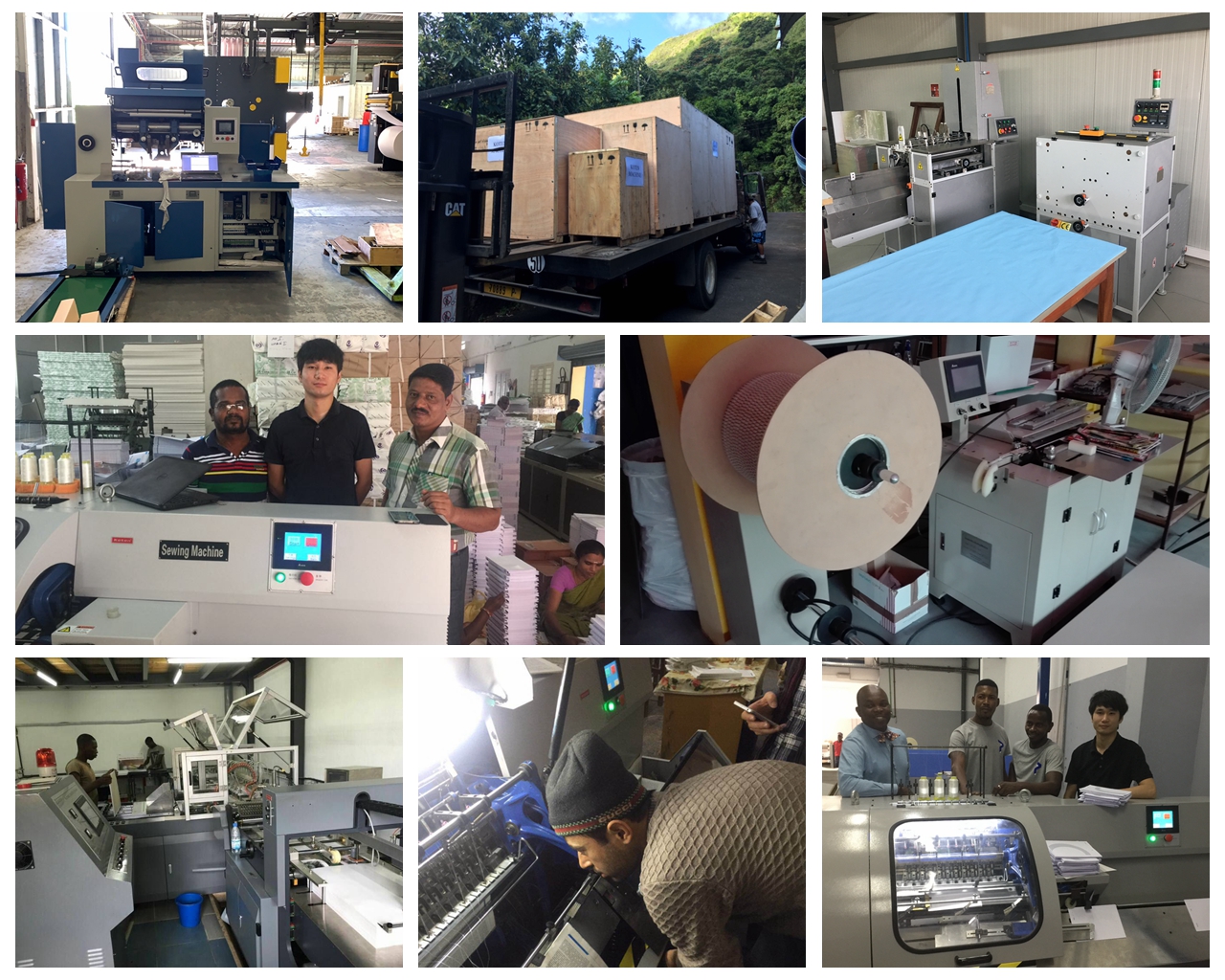

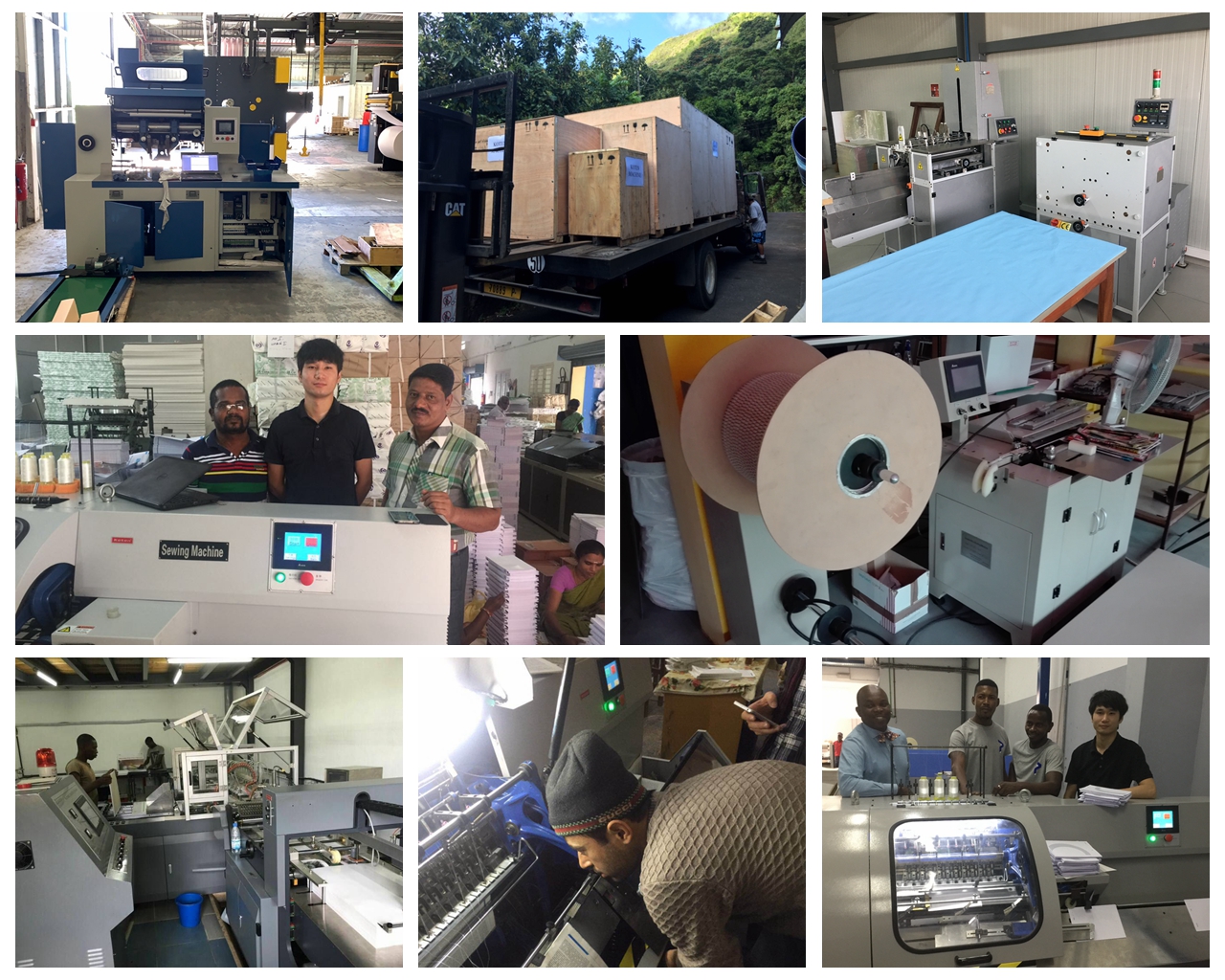

Koten Machines Container Loading.

140 Countries Clients Who Has Koten Brand Machines Till 2019.

2. Guarantee.

3. Delivery Time.

4. What is your package?

5. Do you have Installation and Training service if we bought the machines from your company?

6. Have you sold any machines to our country?

7. What is your payment terms?

8. What your company can offer?

Paper Bag Making Solutions.

Exhibitions and Customers'Meeting.

Factory Production.

Introduction.

Roller Die Cutting machine is to cut the paper with the mould. It can be applied to normal paper, coated paper and cardboard, (the following paper cannot be processed: composite paper (covered with polypropylene) or plastic film). Speed can reach 6000 cycles per hour. It can remove the waste automatically, easy to operate and save time with the efficient work.

1. Operation Console

Both setup and control can be done though the intuitive touch screen. After setting upper and lower die, the system can be set up by simply inputting sheet size and product size. The graphical illustrations on the screen are simple and easy to understand.

2. Feed Section

Vacuum belt feeding enables superior feeding with easy setup and operation. An ultrasonic sensor is used for double feed detection on a wide range of substrates.

3. Transport Section

Sheets are registered by vacuum belt and position is firmly secured with gripper rollers for high quality finish. Servo motor driven gripper rollers ensure the die cut position without effecting processing speed.

4. Die Cutting

Rigid magnetic upper roller and solid lower anvil roller ensure high quality die cutting. Uniquely designed die cutting section enables easy and quick die setting. Both 0.6mm and 0.8mm/0.0236’’ and 0.0315’’ thickness of flexible die plates can be used.

5. Separator

The separator removes the waste from the finished product and delivers it to the waste bin. Air cylinder driven separator pins and sir jets can be used depending on size of the waste.

6. Delivery Section

Finished products are delivered on the motorized conveyor. Intermittent conveyor movement maximizes the continuous operation in a small space. Gap can be adjusted depending on the size of the product for easy handling.

7. Multi-functional system die cutting、kiss cutting creasing、repeat cutting

8. Rotary Die cutting machine (Max.400x550 mm)-Rotary Die-Cutter designed to meet the growing demand.

9. Flexible substrate-Die cut, Crease, Perforation, Silt, Hole punch and round corner in various substrates up to 0.5mm(only for die cutting)thickness for digital and offset printed sheets.

10. One pass processing-Feeding, die cutting and separating are achieved in one pass at a speed of 6,000 cycles per hour.

11. Save the cost of making die-Uniquely designed servo motor controlled ”Repeat Register” feature allows multiple-up applications from single-up die to minimize die cost.

12. Simple and easy operation-Reduces costly labor steps and increases productivity.

A. Sheet Flow.

This section describes the sheet flow from the feed unit through the die cutter and the separator. The separator separates the cut product from the sheet.

DP-4055 Specifications | |||

Sheet feeding system | Vacuum Feed Belts | ||

Sheet Size(before processing) |

Width x Length | Max.400X550mm/15.74X21.65 Min.200X275mm/ 7.88X10.83 | |

Cut product Size The size may be limited depending on shape and sheet weight range. | separator | Max.376X530mm/14.8X20.8 | |

Min.50X80mm/1.97X3.15 | |||

Without separator | Max.384X530mm/15.1X20.8 | ||

Min. Depending on die shape | |||

Processed Material | Normal paper, Coated paper, Cardboard | ||

Material Thickness | 127.9 to 400gsm

0.5mm/0.019 Die cutting:Max.0.5mm/0.019 0.8mm/0.031 (In case of blade height:0.8mm/0.031)

0.3mm/0.001 Die cutting:Max.0.3mm/0.001 0.6mm/0.023 (In case of blade height:0.6mm/0.023)

0.4mm/0.015 Creasing:Max.0.4mm/0.015 0.8mm/0.031 (In case of blade height:0.8mm/0.031) |

Feeder stack Height |

500mm/19.68 |

Die Size Upper Die | Max.400X560mm/15.74X22.04 Min.160X100mm/6.30X3.94 |

Upper Cutting Blade Height |

0.6mm or 0.8mm/0.0236 or 0.0315 |

Production Speed | 6000 个 6000cycles per hour |

Voltage/Frequency | 200-240V,50 / 60Hz Single Phase 200 to 240V,50/60Hz |

Machine Weight | With separator:1200KG Without separator:900KG |

Configuration:

NO. | Configuration | Brand |

| 1. | 10’’ touch screen | AB |

| 2. | Control system | AB |

| 3. | Expansion module | AB |

| 4. | Power module | AB |

| 5. | Communication module | AB |

| 6. | Ending cover | AB |

| 7. | Servo Motor | Panasonnic |

| 8. | Servo driver | AB |

| 9. | Servo cable | AB |

| 10. | Exchange | AB |

| 11. | Communication cable | AB |

| 12. | Encoder | AB |

| 13. | Encoder access module | AB |

| 14. | Transducer | AB |

| 15 | Stepping drive | Kinco |

| 16 | X2 Communication plug | Panasonnic |

| 17. | Stepping motor | Kinco |

Koten Machines Container Loading.

140 Countries Clients Who Has Koten Brand Machines Till 2019.

2. Guarantee.

3. Delivery Time.

4. What is your package?

5. Do you have Installation and Training service if we bought the machines from your company?

6. Have you sold any machines to our country?

7. What is your payment terms?

8. What your company can offer?

Paper Bag Making Solutions.

Exhibitions and Customers'Meeting.

Factory Production.

Sign up for our Zetor newsletter

Business Tel: +86-577-66887790

Fax: +86-577-65615260

E-mail: Master@cn-koten.com

Whasapp/Wechat/Mobile: +86-13958895259

Add:Room 402, Unit One, No.5 Building, North Sunshine Road, Anyang Street, Ruian City, Wenzhou, Zhejiang Province, China. ZIP. 325200