HIS-1050/1450

Koten

HIS-1050/1450

Negotiate

One set

T/T, L/C at sight.

10sets/month

By strong seaworthy wooden cases.

Within 30 days after get the deposit.

China

696

| Availability: | |

|---|---|

| Quantity: | |

Introduction.

The machine adopts the international advanced coating technology , and combines the features of the national industry. It is a kind of UV oil-passing and glazing equipment for paper surface. After being treated by the machine, printed surface will have a higher glossiness with function of antifouling, damp-proof, fade-proof and wear-proof. Especially, the machine adopts the PLC air-knife system,and it could make the paper which over 80g/m2 coating easily. It is therefore the ideal equipment for the processor to promote the glazing quality of printed matter and create higher profit.

Finished Samples.

Main Specifications.

Model | HIS-1050 | HIS-1450 |

Max. sheet size | 730x1050mm | 1100x1450mm |

Min. sheet size | 310x406mm | 350x460mm |

Max. coating size | 720x1030mm | 1090x1440mm |

Suitable Paper Thickness | 128-600gsm | 128-600gsm |

Coating registration accuracy | +0.2mm | +0.2mm |

Max. speed | 7200pcs/h | 6000pcs/h |

Power | 42kw | 47kw |

Machine size | 9576x2300x2010mm | 10247x3600x2300mm |

Machine weight | 8000kg | 9500kg |

High-speed U.V Spot and Overall Coating Machine For Solvent Base | ||||

Standard Equipment Consists Of: | ||||

(1). | Automatic Stream Feeder. | |||

Standard Features: | ||||

1. | Max loading height: 1100mm | |||

2. | Lower-sway front guide; | |||

3. | Continuous rotation press-wheel side guide; | |||

4. | Mechanical and electrical double sheet detector; | |||

5. | Mis-sheet, sheet-misalignment control by photoelectric inductor; | |||

6. | Emergency stop equipment; | |||

7. | Bar against foreign objects; | |||

8. | Protection mechanism of loading table elevation; | |||

(2). | .2- Roller And 2-Cylinder System UV Coating Unit | |||

Standard Features: | ||||

1. | Offset upper-sway pass-sheet device; | |||

2. | Suitable for thin/thick paper pressing roller gripper; | |||

3. | Quick plastic plate clipping, easy assembling, and easy adjustment; | |||

4. | two-roller oil supplying device with fixed oil amount and even oil layer; The two rollers at the head of the | |||

. | main coater for easy changing photopolymer. | |||

5. | Automatic circulation temperature control ele-thermal coating tank with capacity: 40 KG; Supported by | |||

rolling bearing and small resistance and easy maintenance. | ||||

6. | Integrated lubrication for convenient daily maintenance; | |||

7. | Low speed inching motor; | |||

8. | Round hand wheel knob with safety device; | |||

(3). | UV Curing Equipment And Conveyor | |||

3- U.V Lamps Curing Equipment; | ||||

Safety Devices: | ||||

1. | Full/half lamp device, automatic change to half lamp at mis-sheet; | |||

2. | Temperature control device with safety protection; | |||

3. | U.V leak-proof protection hood; | |||

4. | Automatic lamp-off device when conveying net stops; | |||

Teflon net with conveyor; | ||||

Full distance bottom sucker; | ||||

Net belt automatic correction device; | ||||

Conveying net operates at the same time with main machine electric appliances with speed co-adjustment and single | ||||

Micro-adjustment; | ||||

High-speed U.V Spot and Overall Coating Machine For Solvent Base | ||||

(4). | Automatic Delivery Unit | |||

Standard Features: | ||||

1. | Max loading height: 1100mm; | |||

2. | Sheet counter; | |||

3. | Thin paper guiding device; | |||

4. | Safety device for delivery table elevation; | |||

5. | Sucking conveyor; | |||

(5). | Speed Adjustment By Inverter, Terminal Connection, PLC Control | |||

Optional Equipment: | ||||

(6). | Coating Part For Water Base And I.R Drying Unit. | |||

Standard Features: | ||||

1. | Independent varnishing supply device and convenient for changing varnishing type. | |||

2. | High quality and high efficiency drying system. The reflective hood of I.R. Quartz-tube can accumulate heat | |||

on the sheet surface. | ||||

Standard Equipments: | Option. | |||

1. Auto Stream Feeder. | □(a) on the ceramic anilox roll: | |||

2.2-Roller And 2-Cylinder System UV Coater. | □Feeding Non Stop mechanism : | |||

3. UV 3-Lamps Curing Equipment. | □Non Stop Delivery : | |||

4.Automatic Delivery Unit. | □Air conditioning cooling: | |||

5.Water-based coating equipment. | □Pre-Loading Dolly : | |||

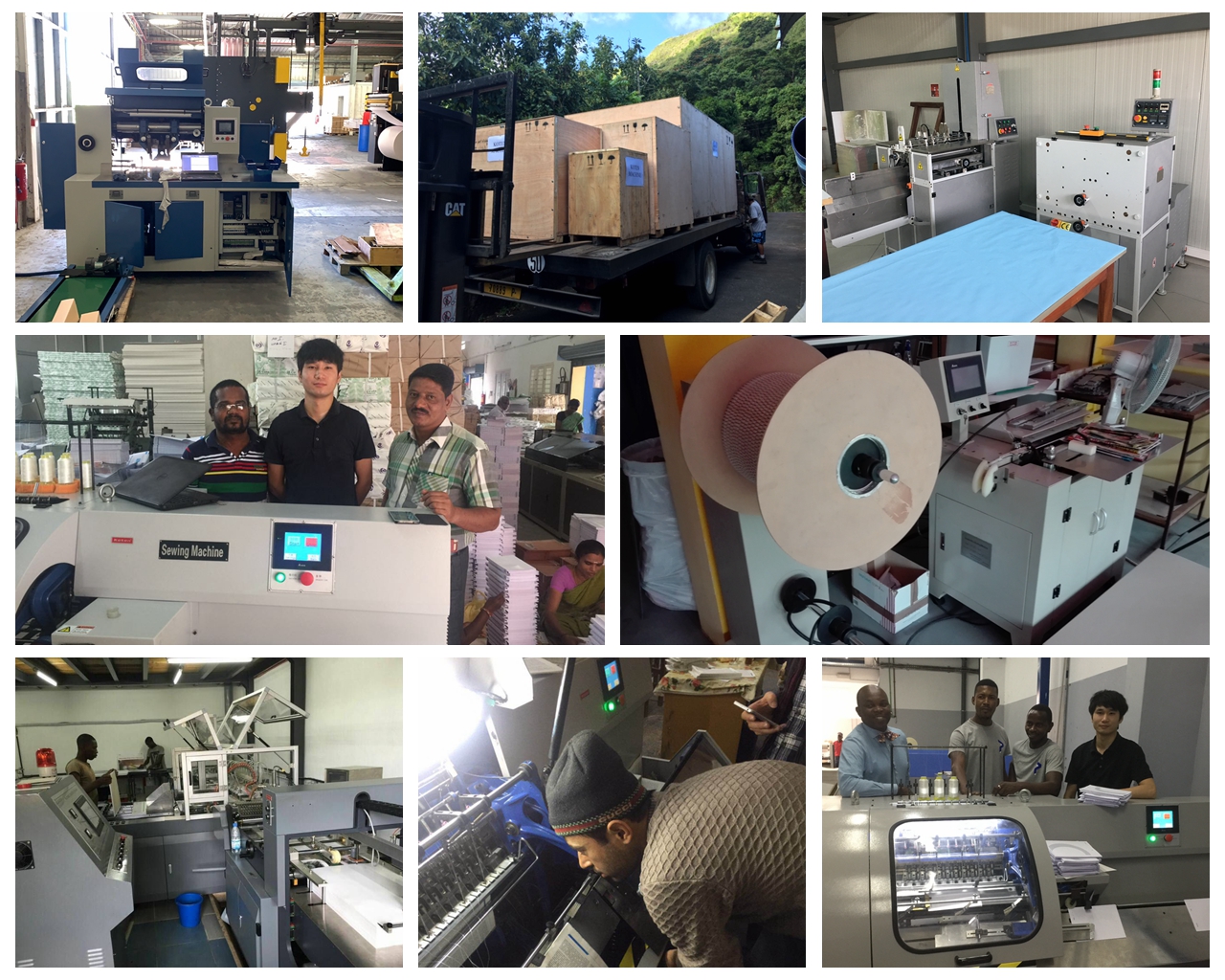

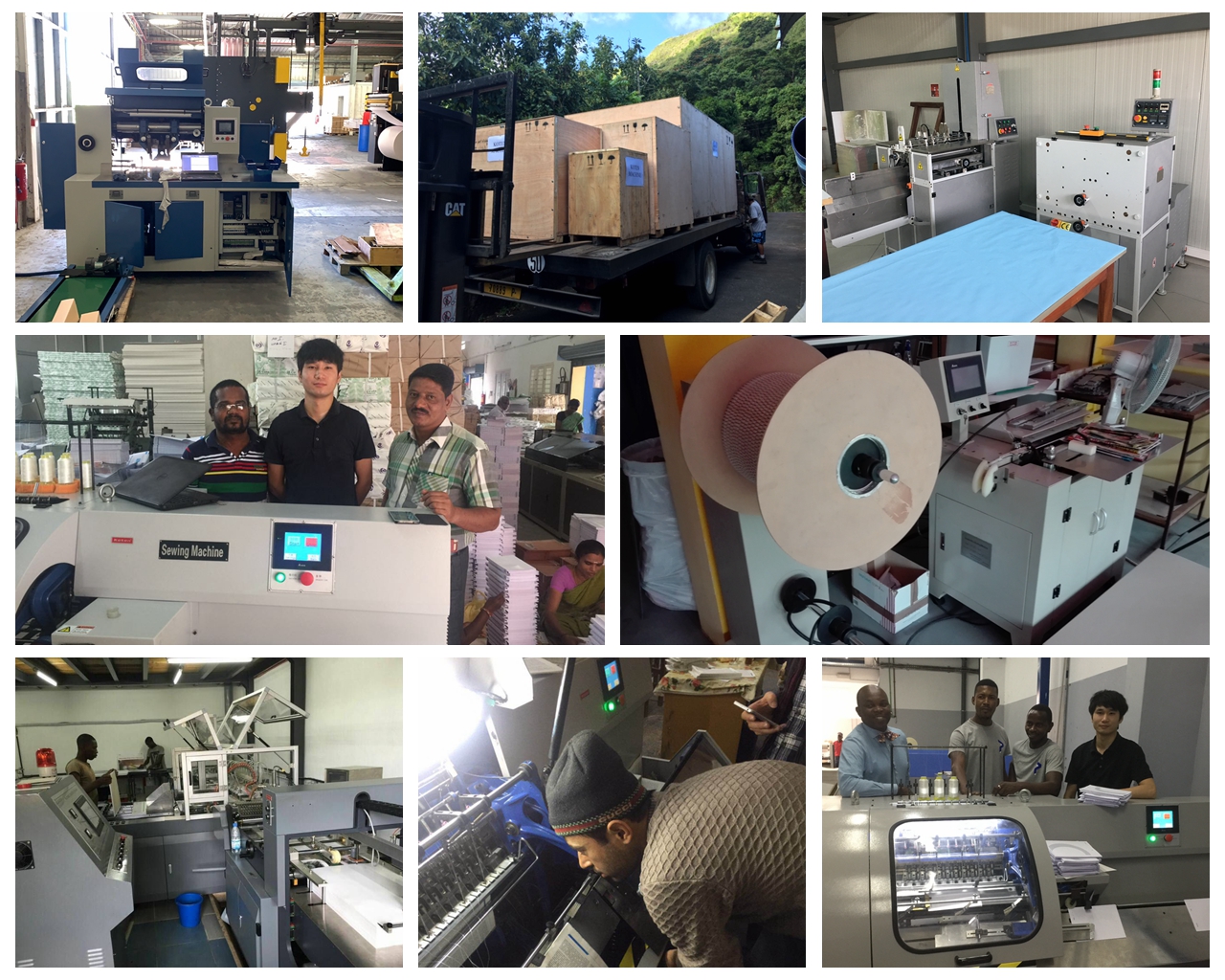

Koten Machines Container Loading.

140 Countries Clients Who Has Koten Brand Machines Till 2019.

2. Guarantee.

3. Delivery Time.

4. What is your package?

5. Do you have Installation and Training service if we bought the machines from your company?

6. Have you sold any machines to our country?

7. What is your payment terms?

8. What your company can offer?

Paper Bag Making Solutions.

Exhibitions and Customers'Meeting.

Factory Production.

Introduction.

The machine adopts the international advanced coating technology , and combines the features of the national industry. It is a kind of UV oil-passing and glazing equipment for paper surface. After being treated by the machine, printed surface will have a higher glossiness with function of antifouling, damp-proof, fade-proof and wear-proof. Especially, the machine adopts the PLC air-knife system,and it could make the paper which over 80g/m2 coating easily. It is therefore the ideal equipment for the processor to promote the glazing quality of printed matter and create higher profit.

Finished Samples.

Main Specifications.

Model | HIS-1050 | HIS-1450 |

Max. sheet size | 730x1050mm | 1100x1450mm |

Min. sheet size | 310x406mm | 350x460mm |

Max. coating size | 720x1030mm | 1090x1440mm |

Suitable Paper Thickness | 128-600gsm | 128-600gsm |

Coating registration accuracy | +0.2mm | +0.2mm |

Max. speed | 7200pcs/h | 6000pcs/h |

Power | 42kw | 47kw |

Machine size | 9576x2300x2010mm | 10247x3600x2300mm |

Machine weight | 8000kg | 9500kg |

High-speed U.V Spot and Overall Coating Machine For Solvent Base | ||||

Standard Equipment Consists Of: | ||||

(1). | Automatic Stream Feeder. | |||

Standard Features: | ||||

1. | Max loading height: 1100mm | |||

2. | Lower-sway front guide; | |||

3. | Continuous rotation press-wheel side guide; | |||

4. | Mechanical and electrical double sheet detector; | |||

5. | Mis-sheet, sheet-misalignment control by photoelectric inductor; | |||

6. | Emergency stop equipment; | |||

7. | Bar against foreign objects; | |||

8. | Protection mechanism of loading table elevation; | |||

(2). | .2- Roller And 2-Cylinder System UV Coating Unit | |||

Standard Features: | ||||

1. | Offset upper-sway pass-sheet device; | |||

2. | Suitable for thin/thick paper pressing roller gripper; | |||

3. | Quick plastic plate clipping, easy assembling, and easy adjustment; | |||

4. | two-roller oil supplying device with fixed oil amount and even oil layer; The two rollers at the head of the | |||

. | main coater for easy changing photopolymer. | |||

5. | Automatic circulation temperature control ele-thermal coating tank with capacity: 40 KG; Supported by | |||

rolling bearing and small resistance and easy maintenance. | ||||

6. | Integrated lubrication for convenient daily maintenance; | |||

7. | Low speed inching motor; | |||

8. | Round hand wheel knob with safety device; | |||

(3). | UV Curing Equipment And Conveyor | |||

3- U.V Lamps Curing Equipment; | ||||

Safety Devices: | ||||

1. | Full/half lamp device, automatic change to half lamp at mis-sheet; | |||

2. | Temperature control device with safety protection; | |||

3. | U.V leak-proof protection hood; | |||

4. | Automatic lamp-off device when conveying net stops; | |||

Teflon net with conveyor; | ||||

Full distance bottom sucker; | ||||

Net belt automatic correction device; | ||||

Conveying net operates at the same time with main machine electric appliances with speed co-adjustment and single | ||||

Micro-adjustment; | ||||

High-speed U.V Spot and Overall Coating Machine For Solvent Base | ||||

(4). | Automatic Delivery Unit | |||

Standard Features: | ||||

1. | Max loading height: 1100mm; | |||

2. | Sheet counter; | |||

3. | Thin paper guiding device; | |||

4. | Safety device for delivery table elevation; | |||

5. | Sucking conveyor; | |||

(5). | Speed Adjustment By Inverter, Terminal Connection, PLC Control | |||

Optional Equipment: | ||||

(6). | Coating Part For Water Base And I.R Drying Unit. | |||

Standard Features: | ||||

1. | Independent varnishing supply device and convenient for changing varnishing type. | |||

2. | High quality and high efficiency drying system. The reflective hood of I.R. Quartz-tube can accumulate heat | |||

on the sheet surface. | ||||

Standard Equipments: | Option. | |||

1. Auto Stream Feeder. | □(a) on the ceramic anilox roll: | |||

2.2-Roller And 2-Cylinder System UV Coater. | □Feeding Non Stop mechanism : | |||

3. UV 3-Lamps Curing Equipment. | □Non Stop Delivery : | |||

4.Automatic Delivery Unit. | □Air conditioning cooling: | |||

5.Water-based coating equipment. | □Pre-Loading Dolly : | |||

Koten Machines Container Loading.

140 Countries Clients Who Has Koten Brand Machines Till 2019.

2. Guarantee.

3. Delivery Time.

4. What is your package?

5. Do you have Installation and Training service if we bought the machines from your company?

6. Have you sold any machines to our country?

7. What is your payment terms?

8. What your company can offer?

Paper Bag Making Solutions.

Exhibitions and Customers'Meeting.

Factory Production.

Sign up for our Zetor newsletter

Business Tel: +86-577-66887790

Fax: +86-577-65615260

E-mail: Master@cn-koten.com

Whasapp/Wechat/Mobile: +86-13958895259

Add:Room 402, Unit One, No.5 Building, North Sunshine Road, Anyang Street, Ruian City, Wenzhou, Zhejiang Province, China. ZIP. 325200