Product Description.

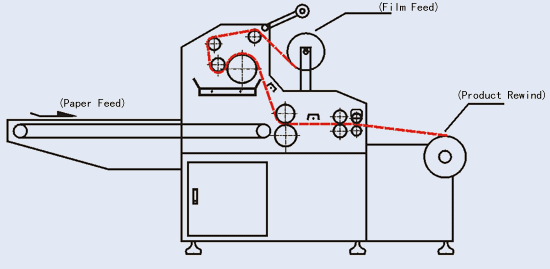

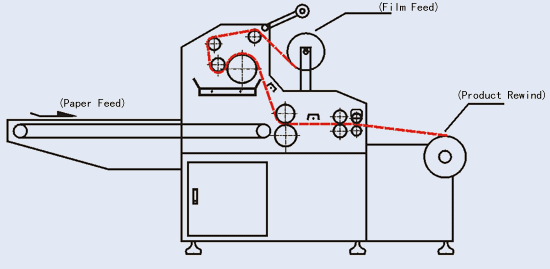

ZFM-1000/1200 automatic water soluble film laminator is a compound machine aiming to water soluble film.

Based on market requirement, we add an automatic paper-feeding unit to original SFM automatic water soluble film laminating machine.

This machine is mainly composed with paper feeding system, laminating system, and paper separating system.

The whole machine is with compact structure and with high degree of automatization and hunmanity Operation, So it could be the choice for large and medium scale laminating enterprises.

Application Scope.

The machine adopts water soluble film for the lamination of packing bags, books,retroperitoneal press work,advertising film, maps and drawings etc.

Function.

The laminated products will be water-proof, durable, of clear picture and spatial effect.

Paper Thickness.

This machine is suitable for lamianting paper with thickness range 105-500gsm.

![OPP Film Cold Laminating Machine OPP Film Cold Laminating Machine]()

Model | ZFM-1000 | ZFM-1200 |

Paper Size | 920*660mm | 1092*787mm |

Temperature | 0-130 | 0-130 |

Paper Thickness | 80-500g/m2 | 80-500g/m2 |

Laminating Speed | 0-75m/min | 0-75m/min |

Total Power | 7.7KW | 7.7KW |

Weight | 2000kg | 2000kg |

Dimensions | 3850x1650x1850mm | 3850x1750x1850mm |

Equipment--AUTOMATIC PAPER CUTTING MACHINE

LZ series Separating and Cutting Machine is a kind of corollary product for laminating machine and is suitable for automatically separating and cutting

various papers laminated on singlepaper laminating machine.With such characteristics as compact structure, high speed, high efficiency,simple and reliable

operation and smooth running, etc,This machines a kind of accessory equipment used in printing plant for improving laminating efficiency.

Products Characteristic

1.The machine adopts cast-iron structure and has such characteristics as long service life and non-deformation.

2.The machine adopts immersion coating method to make coating more uniform and glue-saving,this making the glued coating roller has such characteristics as non-crusting,non-freezing ,easy cleaning, reasonable structure and easy operation.

3.The machine adopts four-roller double pressure laminating to make product quality stable and reliable and itself more suitable for thick and thin paper laminating.

4.With such functions as automatic constant temperature, the glue barrel can prevent glue from freezing and effecting the laminating effect because of too low temperature.

5.Five sets of finished product rolling trolleys equipped with the machine can make products have enough time to solidify.

6.Operating power of the machine is single-phase 220V.Adopting Omron converter made in Japan and imported famous-brand control electric elements, the machine can run steadily without faults.

7.It is equipped with two sets of heating devices.

8.It is equipped with automatic punching device which can effectively improve production efficiency.

Technical Variables.

Model | LZ-1000 | LZ-1200 |

Max. Cutting size | 950x1000mm | 1120x1000mm |

Min. Cutting length | 400mm | 400mm |

Speed | 80m/min | 80m/min |

Power | 1.5kw | 1.5kw |

Machine weight | 500kgs | 600kgs |

Machine size | 3.35x1.45x1.1m | 3.35x1.65x1.1m |

Main Features

1. CE certificate

2.Automatic paper feeder adopts oil-free vacuum pump paper-suction system which is controlled by simply-structured bearing and rotating valve, without need of lubricating, and allowing position adjustment of air-blowing head to paper pile during operation, which improves working efficiency so much.

It is also attached with paper loader lifting protection.

It is equipped with non-paper protector, paper break protector and paper superposing protector, which are controlled by photoelectric and mechanical systems. When no paper, paper break or paper superposition occurs, the machine will stop automatically for self-protection.

With paper number countingfunction.

3. Paper regulating plate is adjustable upon paper size.

4.Oil Heating method:

The heating roller is use heat transfer oil, the temperature meter is inside the oil, not touch with the roller surface, so that get the accurate temperature.

5. Pressuring method: Automatic hydraulic system provides big pressure, and the pressure is adjustable upon laminating requests.

6. Anti-curvature device: The laminated THIN paper goes through anti-curvature device and won’t curl after cutting.

7. Film cutter: If width of film roll is longer than paper’s width or length, then film cutter can cut the redundant film.

Pneumatic cutting system realizes automatic paper cut as long as the operator inputs the size of workable paper on the touch screen.

8. Perforating wheel perforates holes on film edge for automatic cutting to laminated paper.

9. Paper receiving table: Cut paper is sent to paper receiving table. Height of the table is adjustable.

After cut, the laminated paper will be collected by automatic paper collector or be sent automatically to vibrating receiving table and put into order.

10. The machine adopts one-piece structure design which makes the machine running stable and lengthens the machine’s lifetime.

11. Schneider frequency converter realizes infinitely variable speed, and makes the machine’s running easy.

12. Thermal Film Laminating Machine with Automatic Sheeting Easy to operate . The user only should input the paper in the text screen, and then it can both finish laminating and separating processes.

13.The overlap use servo motor control , when operating the machine just need to set the paper length on touch screen, the machine can run automatically , the overlap tolerance is about ±2mm.

14. Adopt the jogger for AUTO collecting the paper, after pneumatic separating paper can collect well with the vibrating table, no need extra people for collection.

15.Hydraulic pressuring system provides automatically big and steady pressure to guarantee good laminating quality.

16.Man-machine interface system: PLC touch screen simplifies the machine operation. On the touch screen, as long as the operator inputs paper size, overlap length and working speed etc., the machine can realize completely automated operation. And on touch screen, working status of the machine can be checked at any time.

17.This machine can be operated by just one person.

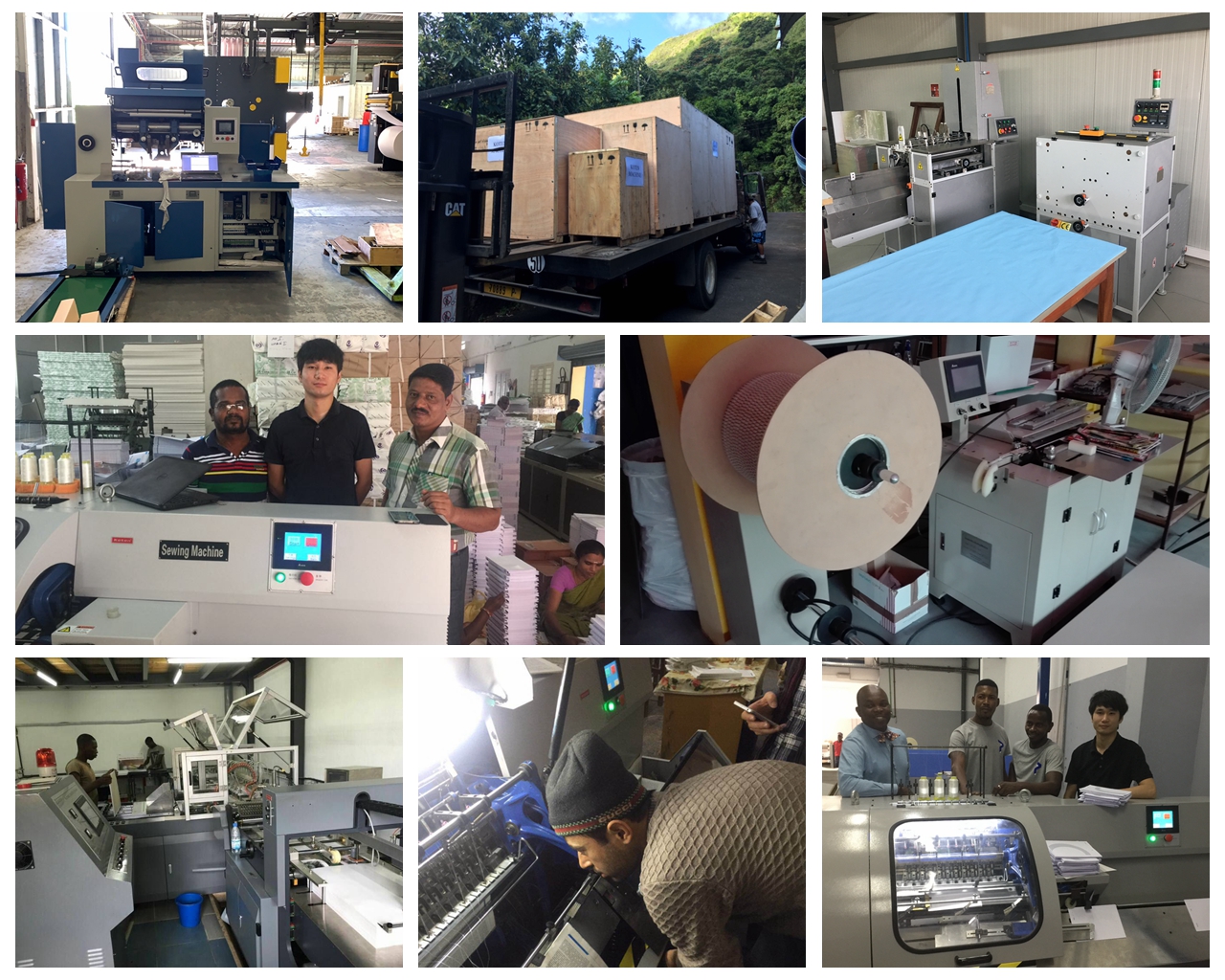

Koten Machines Container Loading.

![OPP Film Cold Laminating Machine packaging OPP Film Cold Laminating Machine packaging]()

140 Countries Clients Who Has Koten Brand Machines Till 2019.

![OPP Film Cold Laminating Machine customers OPP Film Cold Laminating Machine customers]()

FAQ.

1. Why choose us to cooperate?

Factory prices, flexible payment terms and professional quality inspection team which has the guarantee for machines, in time after sales service, and more than 15 years experience for exporting. Reputation and quality is what we are considering all the time.

2. Guarantee.

There is 12 month guarantee of each Koten brand Machines since customer got the machine. Within one year, the damaged spare parts can be changed for free, and we provide lifetime technology support on line.

3. Delivery Time.

Within 7-30 days after get the deposit. Depends on different machines.

4. What is your package?

What the package we use is strong seaworthy wooden cases. Each machine will be protected by anti-rusted oil before put into the case and there are desiccants will be packed into the machine together.

5. Do you have Installation and Training service if we bought the machines from your company?

The training service will be done by our agency dealer in some countries. If customers request us to dispatch our engineer to their country for installation and training, customers should take all necessary cost, like return flight tickets, hotel, food and salary USD100/day. If customer dispatch their engineer to our factory for training, it is free.

6. Have you sold any machines to our country?

We have to say that there are 140 countries' customers who have the "KOTEN" brand machines till 2019. Pls check with the sales manager to get more information if you need the machines' feedback.

7. What is your payment terms?

T/T. If the amount less than USD30,000.00, 30% paid in advance as a deposit, 70% balance paid before shipment.

L/C. If the sales amount above USD30,000.00, 30% paid by T/T as a deposit, 70% balance paid by irrevocable L/C at sight.

By Cash, by western union, credit cards are acceptable.

Special country like Bangladesh or Algeria can be available for 100% by irrevocable L/C at sight.

8. What your company can offer?

Exercise Books Making Solutions.

Soft Cover Books Making Solutions.

Hard Cover Books Making Solutions.

Spiral Books Making Solutions.

Postpress and Paper Converting Solutions.

Paper Box Making Solutions.

Rigid Box Making Solutions.

Paper Bag Making Solutions.

Exhibitions and Customers'Meeting.

![OPP Film Cold Laminating Machine exhibition OPP Film Cold Laminating Machine exhibition]()

Factory Production.

![OPP Film Cold Laminating Machine factory OPP Film Cold Laminating Machine factory]()