Introduction.

JB-A Series full automtic stop cylinder screen press which adopts the classical stop cylinder technology with the advantages such as:paper located exactly and steadily,high precision,high speed,low noise,high degree auto matizaton and so on,it is suitable for printing on ceramic and glass applique,electron industry(film switch,flexible circuitry,meter panel,moblie telephone),advertisment,packing and printing,brand,textile transfer,special technics etc.

Characteristics

1.Classical stop cylinder mechanism,sylinder stops step automatically to ensure the forehead of the printing stock can be sent accurately to the girpper of cylinder,which is up to extreme highprecision:

at the same time,gripper of cylinder and pull side-lay both have the magic eyes for supervising if the printing stock is in correct place ,which can reduce the waster effectively.

2.The bottom of convey table with vacuum adsorption,assermbled with the pull and press mechanism,ensure printing stock deliveryed smoothly.

3.Two cams separately control the movement of squeegee and ink -return blade:squeegee with the pneumatical pressure kept devic,the printing graphics is more clearly and the ink layer is more well-proportioned.

4.The screen frame rack can be pulled out,which is easy for adjusting the register or feeding,as well as cleaning the cylinder and screen frame;at the same time,it is assembled with device to hold the ink dropped to avoid the ink drops on the cylinder.

5.Main transmission and main parts lubricate automatically,prolong the using precision and machine life in effect.

6.The whole machine controlled by PLC,can choose touch screen for operating,which is vrey easy and high degree automatism.

7.It can be used with JB Series screen drying machine,UV dryer,UV & IR dryer and automatic stacker to form the full automatic scree printing line.

Main Technical variables |

Model | JB-720A | JB-800A | JB-1020A | |

Max.paper size

Min.paper size

Max.printing size | 720x520mm2

350x270mm2

720x500mm2 | 800x600mm2

350x270mm2

800x590mm2 | 1020x720mm2

560x350mm2

1020x710mm2 | |

Paper thickness

Border | 108-400g/m2

10mm | 108-400g/m2

10mm | 120-400g/m2

10mm | |

Printing speed

Power

Total weight

Overall size | 1000-3600pcs/h

3P 380V 50Hz 7.8KW

3500KG 4200x2400x1600mm | 1000-3300pcs/h

3P 380V 50Hz 7.8KW

3800KG

4300x2550x1600mm | 1000-3000pcs/h

3P 380V 50Hz 10.5KW

5000KG

4800x2800x1600mm | |

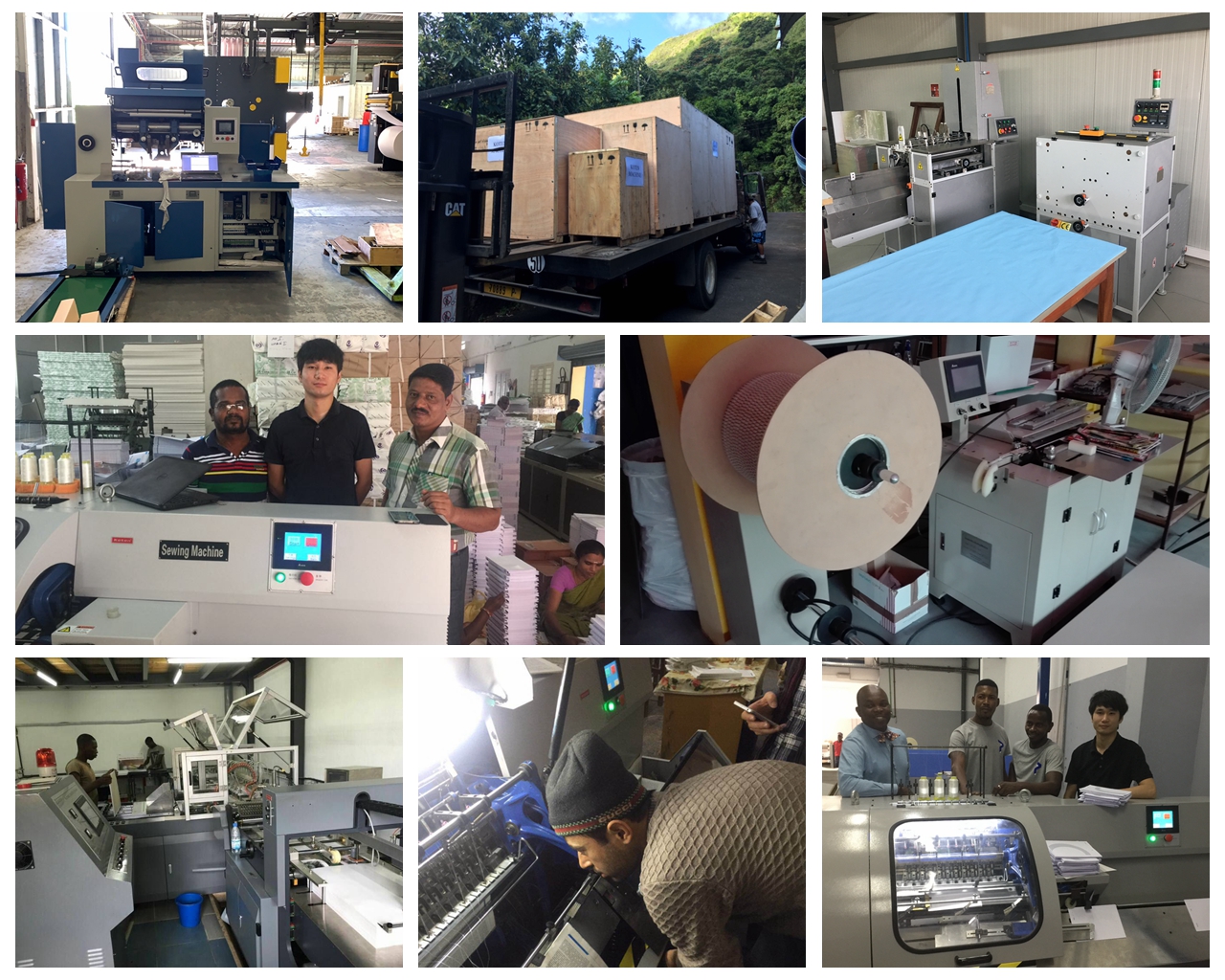

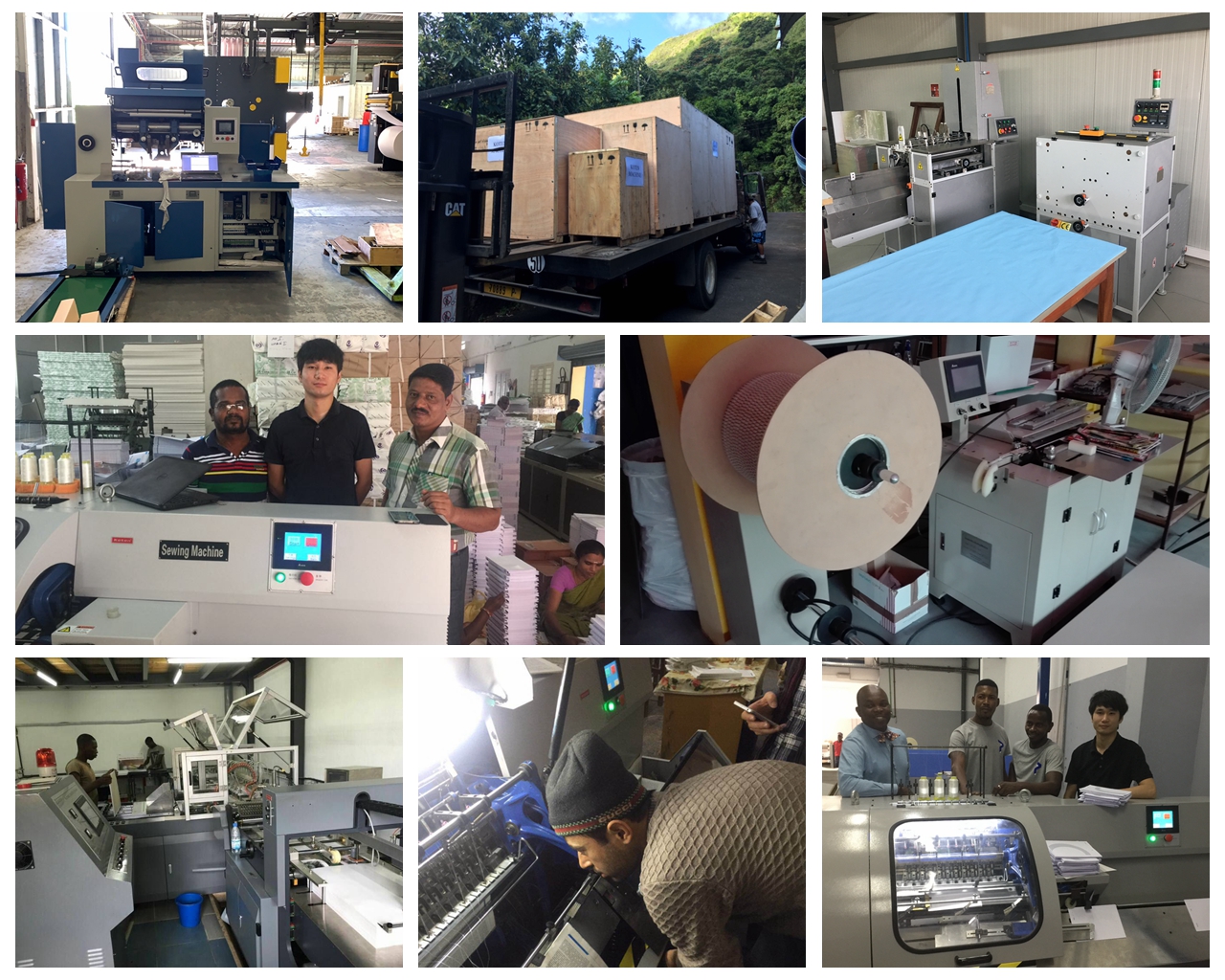

Koten Machines Container Loading.

![Automatic Screen Press Automatic Screen Press]()

140 Countries Clients Who Has Koten Brand Machines Till 2019.

![Automatic Screen Press Automatic Screen Press]()

FAQ.

1. Why choose us to cooperate?

Factory prices, flexible payment terms and professional quality inspection team which has the guarantee for machines, in time after sales service, and more than 15 years experience for exporting. Reputation and quality is what we are considering all the time.

2. Guarantee.

There is 12 month guarantee of each Koten brand Machines since customer got the machine. Within one year, the damaged spare parts can be changed for free, and we provide lifetime technology support on line.

3. Delivery Time.

Within 7-30 days after get the deposit. Depends on different machines.

4. What is your package?

What the package we use is strong seaworthy wooden cases. Each machine will be protected by anti-rusted oil before put into the case and there are desiccants will be packed into the machine together.

5. Do you have Installation and Training service if we bought the machines from your company?

The training service will be done by our agency dealer in some countries. If customers request us to dispatch our engineer to their country for installation and training, customers should take all necessary cost, like return flight tickets, hotel, food and salary USD100/day. If customer dispatch their engineer to our factory for training, it is free.

6. Have you sold any machines to our country?

We have to say that there are 140 countries' customers who have the "KOTEN" brand machines till 2019. Pls check with the sales manager to get more information if you need the machines' feedback.

7. What is your payment terms?

T/T. If the amount less than USD30,000.00, 30% paid in advance as a deposit, 70% balance paid before shipment.

L/C. If the sales amount above USD30,000.00, 30% paid by T/T as a deposit, 70% balance paid by irrevocable L/C at sight.

By Cash, by western union, credit cards are acceptable.

Special country like Bangladesh or Algeria can be available for 100% by irrevocable L/C at sight.

8. What your company can offer?

Exercise Books Making Solutions.

Soft Cover Books Making Solutions.

Hard Cover Books Making Solutions.

Spiral Books Making Solutions.

Postpress and Paper Converting Solutions.

Paper Box Making Solutions.

Rigid Box Making Solutions.

Paper Bag Making Solutions.

Exhibitions and Customers'Meeting.

![Automatic Screen Press Automatic Screen Press]()

Factory Production.

![Automatic Screen Press Automatic Screen Press]()