Views: 0 Author: Site Editor Publish Time: 2025-11-03 Origin: Site

In today’s competitive printing and publishing world, choosing the right Soft Cover Book Solution can make a major difference in cost, quality, and brand perception. Whether you are a self-publisher, an educational institution, or a business producing manuals, catalogs, or marketing materials, soft cover books remain a versatile and affordable option. However, the range of materials, binding methods, and finishing technologies available today can make the decision process challenging.

A soft cover book, also known as a paperback, features a flexible cover typically made of cardstock or coated paper rather than a rigid board. Despite being lighter and less costly than hardcovers, modern soft cover books can achieve a highly professional appearance through advanced printing and finishing options.

Soft cover books are popular for novels, magazines, product catalogs, training manuals, and even coffee-table books when printed on high-quality paper. The flexibility in customization—combined with fast production and lower costs—makes them ideal for both large-scale commercial use and small print runs.

Choosing a soft cover format comes with multiple advantages:

Cost Efficiency: Soft cover books are significantly cheaper to produce than hardcover alternatives, especially for bulk orders.

Lightweight and Portable: Their flexible construction makes them easier to handle and ship, reducing logistics costs.

Fast Production Time: Ideal for time-sensitive projects such as seasonal catalogs or limited-edition releases.

Design Flexibility: With the right printing technology, soft cover books can feature high-resolution graphics, matte or gloss lamination, and spot UV finishes.

Eco-Friendly Options: Many manufacturers now offer recycled or FSC-certified papers and soy-based inks for sustainability.

These benefits make soft cover solutions highly practical for businesses seeking professional presentation without excessive costs.

Selecting the right Soft Cover Book Solution involves more than just deciding how your book should look—it’s about balancing cost, durability, design impact, and practicality. Whether you are printing marketing catalogs, novels, or training manuals, each factor contributes to the final quality and perception of your book. Below are the most important aspects to evaluate before choosing your production plan.

The binding method you select determines the overall appearance, usability, and durability of your book. Soft cover books can be bound in several ways, each suited to specific applications:

Binding Type | Description | Best For |

Perfect Binding | Uses a strong adhesive to attach pages to the spine, creating a clean, square finish. Offers a professional look and allows for spine printing. | Novels, corporate catalogs, manuals, annual reports |

Saddle Stitching | Pages are folded and stapled through the centerfold. It’s simple, lightweight, and affordable but limited to thinner booklets. | Magazines, brochures, newsletters, event programs |

PUR Binding | Employs polyurethane adhesive, offering superior flexibility and strength compared to traditional hot glue. | Thick catalogs, textbooks, high-end presentations |

Spiral/Wire Binding | Uses a plastic or metal coil inserted through punched holes, allowing pages to lay flat and turn 360°. | Instruction manuals, training guides, workbooks |

If your book is meant for long-term use or heavy handling, perfect or PUR binding provides the most durability and a premium aesthetic. For shorter publications or marketing materials, saddle stitching is an economical and fast option. Meanwhile, spiral binding offers practicality and ease of use—especially for manuals or notebooks that need to lay flat.

Paper selection has a major influence on how your book feels in the reader’s hands and how your content appears on the page. The right combination of paper type and weight ensures both aesthetic appeal and functionality.

Interior Paper: The inside pages determine the readability and visual impact of your book.

Matte Paper: Ideal for text-heavy books, providing a smooth, non-glare surface that enhances legibility.

Gloss Paper: Offers sharp image contrast and vibrant colors, perfect for photo-centric content such as product catalogs or magazines.

Uncoated Paper: Provides a natural texture suitable for journals or artistic publications.

Cover Stock: A strong and visually appealing cover protects your content while shaping the reader’s first impression.

Choose a heavier paper between 250–350 gsm for stability.

Add gloss or matte lamination for extra protection and a polished finish. Matte lamination gives a modern, elegant look, while gloss enhances color richness.

Sustainability: With growing environmental awareness, many organizations prefer eco-friendly solutions. Opt for FSC-certified, recycled, or acid-free paper to minimize your ecological footprint.

When producing high-resolution images or color illustrations, coated papers deliver crisp detail and consistent tone reproduction. Conversely, matte or uncoated papers reduce glare and eye strain, making them ideal for professional manuals and educational materials.

Your choice of printing technology directly affects print quality, color accuracy, and production cost. Modern Soft Cover Book Solutions utilize advanced printing methods to deliver precision and consistency across every copy.

Digital Printing:

Ideal for short runs or on-demand projects. Digital printing eliminates the need for setup plates, reducing turnaround time and waste. It also supports variable data printing, allowing unique text or images on each copy—perfect for personalized publications or limited editions.

Offset Printing:

The go-to choice for large production runs. Offset printing offers excellent color consistency, sharper details, and cost efficiency for bulk orders. It is particularly suitable for professional publications that demand perfect image reproduction and smooth gradients.

UV Printing:

This technology uses ultraviolet light to cure ink instantly, enabling unique surface finishes such as spot UV, textured coatings, or metallic effects. UV printing enhances the tactile and visual quality of book covers, making them stand out on shelves or at trade shows.

Selecting the right printing technology ensures that your final product maintains clarity, vibrancy, and brand integrity while staying within your budget.

A book’s cover is more than just protection—it’s a marketing tool and a statement of brand identity. High-quality finishing options can significantly elevate your publication’s perceived value and professional appeal.

Lamination: Choose between gloss, matte, or soft-touch finishes. Gloss lamination adds brilliance and contrast; matte provides sophistication and reduces fingerprints; soft-touch offers a luxurious, velvety texture.

Foil Stamping: Metallic foils in gold, silver, or other colors add elegance and help titles or logos stand out.

Embossing/Debossing: Adds a tactile 3D effect that enhances visual hierarchy and design depth.

Spot UV Coating: Highlights specific design elements, such as logos or images, with a glossy, raised layer for emphasis.

When designed effectively, a well-crafted cover not only protects your content but also communicates creativity, quality, and attention to detail—key factors in influencing readers’ perceptions and purchase decisions.

Durability plays a critical role in projects intended for frequent use, such as training manuals, catalogs, or educational books. Frequent handling can lead to spine cracking, page loosening, or cover wear if the wrong materials or adhesives are chosen.

PUR binding stands out for its superior flexibility and temperature resistance—it prevents pages from detaching, even under heavy use or humidity changes. For covers, laminated finishes (especially matte or soft-touch) add a layer of protection against scratches, moisture, and fading, ensuring your books retain their professional look over time.

Finally, consider how many copies you plan to produce and how much you can invest per unit.

For small quantities or test batches, digital printing provides cost efficiency and flexibility without sacrificing quality.

For large-scale production, offset printing significantly reduces per-unit costs while maintaining consistent results.

Always discuss bulk pricing, production schedules, and shipping timelines with your supplier before confirming your order to ensure smooth delivery.

A reliable printer will help you balance cost and quality, offering material and process recommendations based on your goals.

Each type of soft cover book has unique requirements. Below are common use cases and recommended solutions:

Application | Recommended Binding | Paper Type | Special Finish |

Product Catalog | Perfect or PUR Binding | Gloss Coated 150–200 gsm | Matte Lamination |

Magazine | Saddle Stitching | Gloss or Silk 120–170 gsm | Spot UV Highlights |

Training Manual | Wire Binding | Matte 100–150 gsm | None (for easy flipping) |

Company Profile | Perfect Binding | Premium Matte 150 gsm | Embossed Logo |

Art Portfolio | PUR Binding | Heavy Gloss 200 gsm | Soft-Touch Cover |

Choosing the correct configuration ensures your final product meets the intended purpose while maintaining cost-effectiveness.

Choosing the right Soft Cover Book Solution is about understanding your project’s needs, from design and binding to sustainability and cost. A carefully chosen combination of paper quality, binding style, and finishing can elevate your publication’s visual appeal and professional impact.

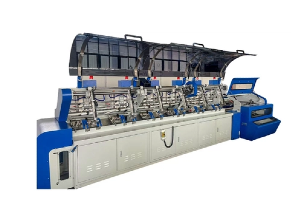

If you’re looking for a trusted partner to bring your soft cover book project to life, www.cn-koten.com is a great place to start.www.cn-koten.com specializes in advanced bookbinding and printing solutions that combine precision engineering with efficiency and flexibility. Whether you need short-run digital printing or large-scale offset production, their expertise can help you achieve the perfect balance of quality and affordability.

For publishers, designers, and businesses seeking reliable and sustainable Soft Cover Book Solutions, collaborating with a professional manufacturer like Koten Machinery can ensure your books make a lasting impression—both visually and economically.

Sign up for our Zetor newsletter

Business Tel: +86-577-66887790

Fax: +86-577-65615260

E-mail: Master@cn-koten.com

Whasapp/Wechat/Mobile: +86-13958895259

Add:Room 402, Unit One, No.5 Building, North Sunshine Road, Anyang Street, Ruian City, Wenzhou, Zhejiang Province, China. ZIP. 325200