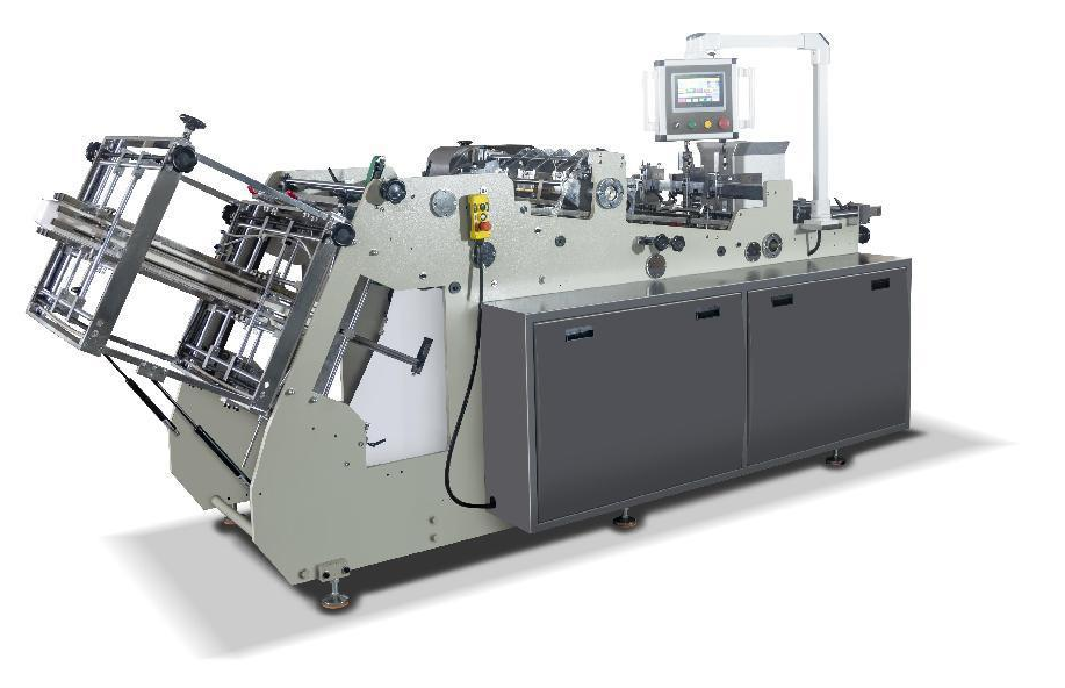

ZF-800 PLUS

KOTEN

ZF-800 PLUS

1 pc

30% deposit 70% final payment

By strong seaworthy export packing

30 days

China

| Availability: | |

|---|---|

| Quantity: | |

ZF-800PLUS is an ideal choice to produce hamburger boxes,chips boxes,takeout container,etc. It adopts micro-computer , PLC , alternating current frequency converter , the vacuum-sucking paper feeding , auto gluing, automatic paper tape counting,chain drive . All of these main parts and electric control system adopts imported brand to guarantee steady working , precise positioning, smooth running , safety and reliability operation.

The carton erecting machine is highly efficient.The working speed of double station model is 50-200pieces per minute and finished produces are automatically counted.It can do different size and shape boxes through changing mold.

设备工作达到50-200个每分钟,并且由插标装置自动成品计数;可通过换模具对不同种类的产品进行糊盒成型。

2.The machine adopts chain drive to guarantee smooth running.

设备采用链条传动方式代替之前的皮带传动方式,运行稳定,经久耐用。具有噪音低,负荷小,稳定高。

3.Automatic gluing system controlled by reduce motor from china. Gluing point is made of sponge and adjusted convenient.

采用电机控制,全自动上胶系统。注胶方便,胶点自由灵活调节,简便易懂。

4.Every parts of forming and collecting system can be adjusted according to the size of mold.The whole collection system can be opened to change mold and install the forming parts conveniently.

成型收料系统各部件可以根据模具尺寸自由调节;整体可打开与设备分离,便于更换,清洁模具,安装成型配件。

Type | ZF-800 PLUS |

Production capacity | 50-300 pcs/min |

Suitable Material: | 200-600 g/m2 card paper max corrugating thickness:1.5mm |

Length: | L100-650mm degree:5°-40° |

Width: | B:100-500mm Hight H15-200mm |

Total Power: | 8kw(FOUR sever motor) |

Total Weight: | 2.2T |

Overall Dimension: | 3600 x 1600 x 1600 mm |

Power source | 380V 50HZ |

下纸伺服电机 DOWN PAPER servomotor | innovance |

成型独立伺服电机 Forming independent servo motor | innovance |

送纸独立伺服电机 Independent servo motor for paper feeding | innovance |

胶水电机 Gluing | innovance |

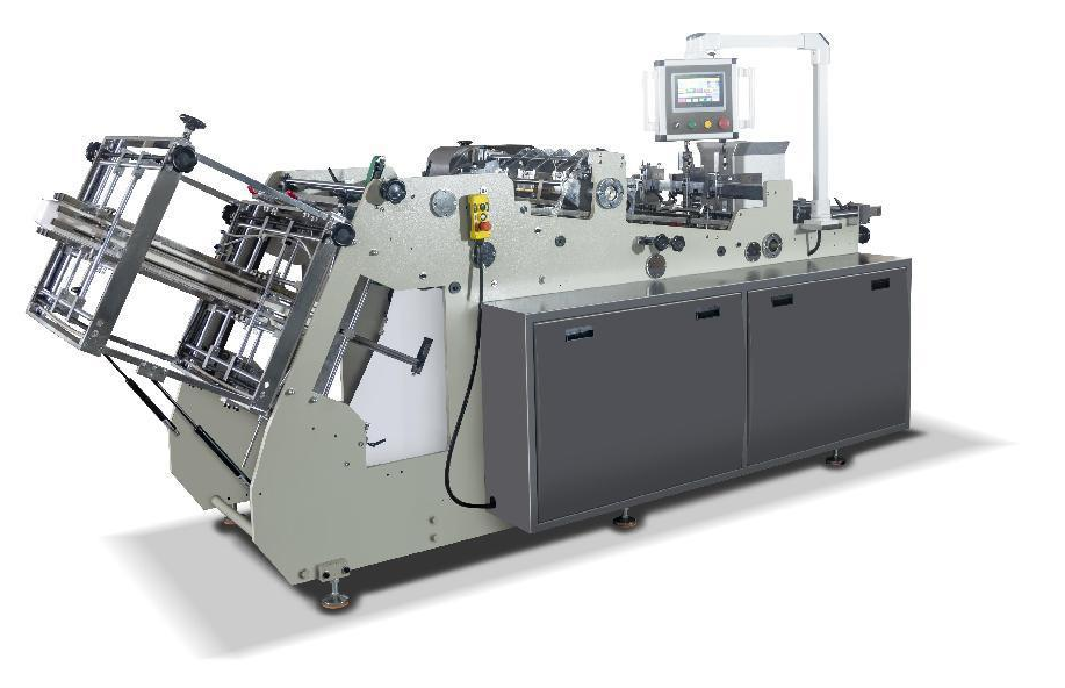

ZF-800PLUS is an ideal choice to produce hamburger boxes,chips boxes,takeout container,etc. It adopts micro-computer , PLC , alternating current frequency converter , the vacuum-sucking paper feeding , auto gluing, automatic paper tape counting,chain drive . All of these main parts and electric control system adopts imported brand to guarantee steady working , precise positioning, smooth running , safety and reliability operation.

The carton erecting machine is highly efficient.The working speed of double station model is 50-200pieces per minute and finished produces are automatically counted.It can do different size and shape boxes through changing mold.

设备工作达到50-200个每分钟,并且由插标装置自动成品计数;可通过换模具对不同种类的产品进行糊盒成型。

2.The machine adopts chain drive to guarantee smooth running.

设备采用链条传动方式代替之前的皮带传动方式,运行稳定,经久耐用。具有噪音低,负荷小,稳定高。

3.Automatic gluing system controlled by reduce motor from china. Gluing point is made of sponge and adjusted convenient.

采用电机控制,全自动上胶系统。注胶方便,胶点自由灵活调节,简便易懂。

4.Every parts of forming and collecting system can be adjusted according to the size of mold.The whole collection system can be opened to change mold and install the forming parts conveniently.

成型收料系统各部件可以根据模具尺寸自由调节;整体可打开与设备分离,便于更换,清洁模具,安装成型配件。

Type | ZF-800 PLUS |

Production capacity | 50-300 pcs/min |

Suitable Material: | 200-600 g/m2 card paper max corrugating thickness:1.5mm |

Length: | L100-650mm degree:5°-40° |

Width: | B:100-500mm Hight H15-200mm |

Total Power: | 8kw(FOUR sever motor) |

Total Weight: | 2.2T |

Overall Dimension: | 3600 x 1600 x 1600 mm |

Power source | 380V 50HZ |

下纸伺服电机 DOWN PAPER servomotor | innovance |

成型独立伺服电机 Forming independent servo motor | innovance |

送纸独立伺服电机 Independent servo motor for paper feeding | innovance |

胶水电机 Gluing | innovance |

Sign up for our Zetor newsletter

Business Tel: +86-577-66887790

Fax: +86-577-65615260

E-mail: Master@cn-koten.com

Whasapp/Wechat/Mobile: +86-13958895259

Add:Room 402, Unit One, No.5 Building, North Sunshine Road, Anyang Street, Ruian City, Wenzhou, Zhejiang Province, China. ZIP. 325200