S400B-1100/1300/1500/1700

Koten

S400B-1100/1300/1500/1700

Negotiate

One Set

T/T

50sets/month

Strong seaworthy wooden cases

Within 30 days after get the deposit.

China

293

| Availability: | |

|---|---|

| Quantity: | |

Usage:

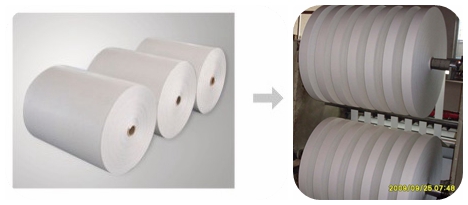

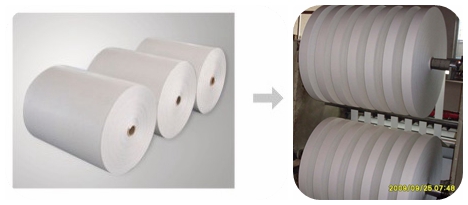

The machine applies to slit cellophane, PET, OPP, CPP, PE, PS, PVC and computer security labels, electronic computers, optical materials, film roll, foil roll, all kinds of paper rolls, film and printing of various materials.,etc

Main mechanical configuration:

1, Main body unit:

1. Machine’s main body adopts cast iron and steel structure.(cast iron after secondary operation and setting treatment)

2. Main driving roller adopts seamless steel pipe (after tempering, surface hardening, chrome plated, mirror surface, dynamic balance treatment)

3. Main driving press roller adopts rubber roll (nitrile-butadiene rubber)

4. Material guide rollers adopts steel rolls (aluminum alloy) and rubber roll (nitrile-butadiene rubber)

5. Driving mode of main body and rewind shafts adopt synchronizing wheel and belt.

2, Unwinding unit:

1. Unwind unit adopts one-piece structure.

2. It adopts removable bracket with ball slider.

3. Non-axial Air pressure and get way with Air Chuck, who is caught taking raw materials fast, easy loading, single-person operation

4. 1 set bias adjustable device can fine tune left and right, forward and backward through hand wheel.

5. Unwind tension’s actuator is 2 sets 50N/M magnetic powder brake. through PLC to achieve a constant tension.

6. EPC uses Germany brand E+L corrective device, it can achieve guide function by material’s edge

3. Rewinding unit:

1. Shafts adopt 3 inch pneumatic fall slip shaft which is controlled by proportional valve.

2. Lock mode adopts pneumatic control.

3. Rewind tension’s actuator is 2 sets Japanese brand SMC proportional valve. through PLC to achieve a constant tension.

4. Rewind press rollers provided by customers demand (2 sets)

5. Slitting knives are controlled by pneumatic cylinder (10 sets). Can be fine tuned. (Circle knife is optional).

6. Equipped with a vacuum-type waste edge exclusion system, use the strong force adsorb the waste edge out away

7. Equipped with a discharge rack which can provide a larger diameter of the finished product. Simple and efficient to operate and save time for the next feed.

4. Electrical equipment unit:

1. Main motor inverter adopts 1 pc Japanese brand Yaskawa vector inverter.

2. Main motor adopts 1 pc Germany brand Siemens vector motor.

3. Rewind motor inverter adopts 1 pc Japanese brand Yaskawa vector inverter.

4. Rewind motor inverter adopts 1 pc Germany brand Siemens vector motor.

5. EPC adopts analog control. Driving by servo motor through ultrasonic signal.

6. Adopts imported PLC to achieve accurate and stable control, true color touch screen display to enable simple and beautiful images. Interactive parameter setting the environment, eliminating the complicated configuration can start the job: The user pre-start only need to input the material thickness, width, density, diameter and speed parameters, the next will be done automatically by a computer calculation to complete.

7. With the functions of automatic and manual acceleration and deceleration.

8. Electrostatic elimination Unit(optional device): The machine equipped a group of static brush apart on up and down rewinding shaft , which can effectively eliminate the static between slitting and rewinding .

Main technical parameter:

Model | S400B-1100 | S400B-1300 | S400B-1500 | S400B-1700 |

Max. Speed | 400m/min | |||

Slitting Width | 30-1100mm | 30-1300mm | 30-1500mm | 30-1700mm |

Rewinding Diameter | 600mm | |||

Unwinding Diameter | 1200mm | |||

Slitting Precision | ±0.1mm | |||

Loading Weight | 1.5T | |||

Dimension | 4254×3300×1990 | 4454×3300×1990 | 4654×3300×1990 | 4854×3300×1990 |

Weight | 5.7T | 6T | 6.3T | 6.8T |

Power | 27KW | 29KW | 32KW | 34KW |

Power Supply | 380V/50HZ | |||

Applicable Materials | Aluminium Foil/PE/Self-adhesive paper/Kraft paper/Cardboard/Coated Paper and other paper products | |||

Main configuration:

Name | Brand | Origin | |

1 | PLC | Siemens | Germany |

2 | Servo Motor(Unwinding) | GTAKE 7.5KW | China |

3 | Servo Motor(Rewinding) | GTAKE 7.5KW | China |

4 | Frequency converter | GTAKE | China |

5 | Pneumatic components | AIRTAC | Taiwan |

6 | Proportional valve | SMC | Japan |

7 | EPC | ARISE | China |

8 | Bearing | NSK | Japan |

9 | Touch Screen | MCGS | China |

10 | Low Voltage Apparatus | Schneider | France |

11 | Button | Schneider | France |

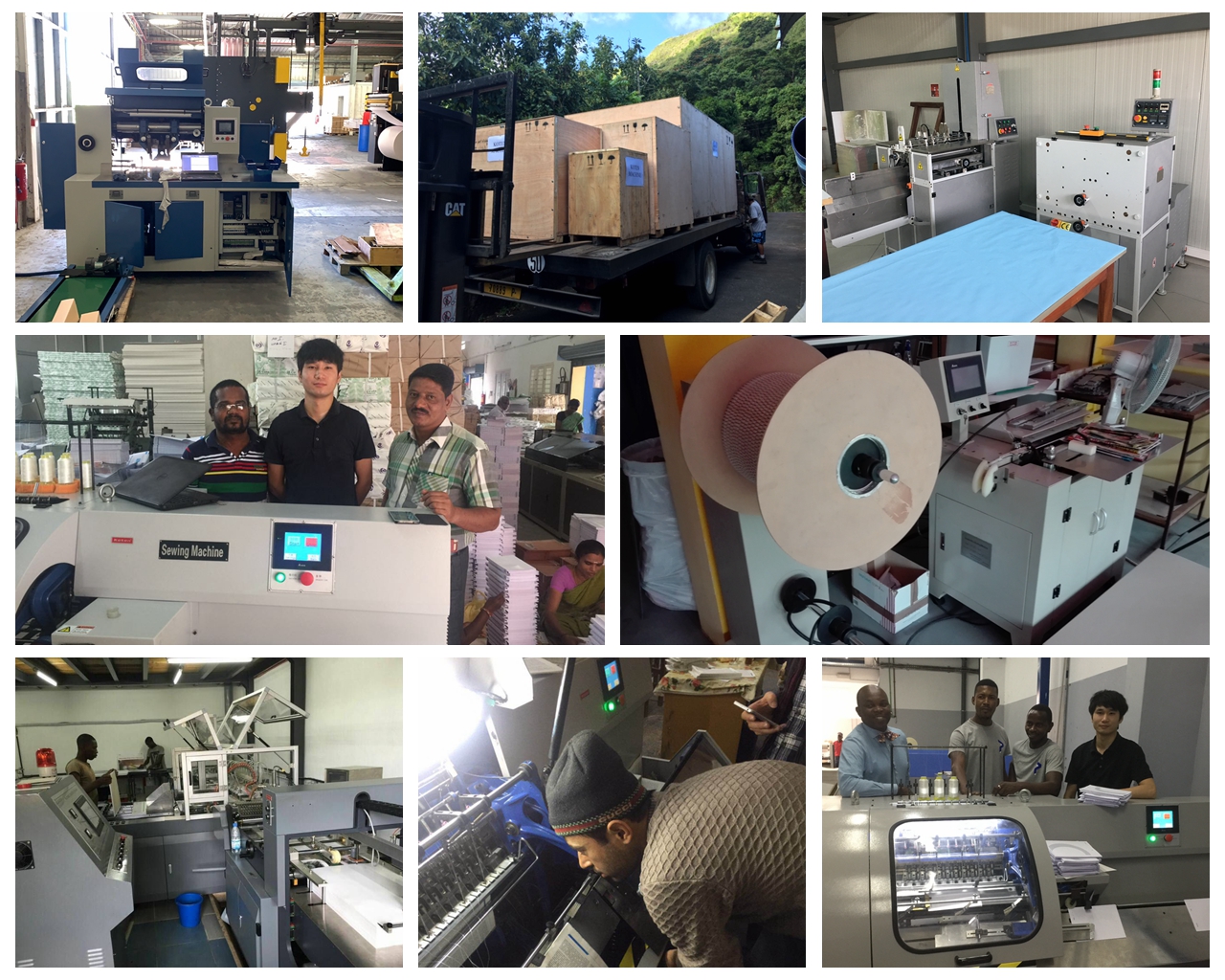

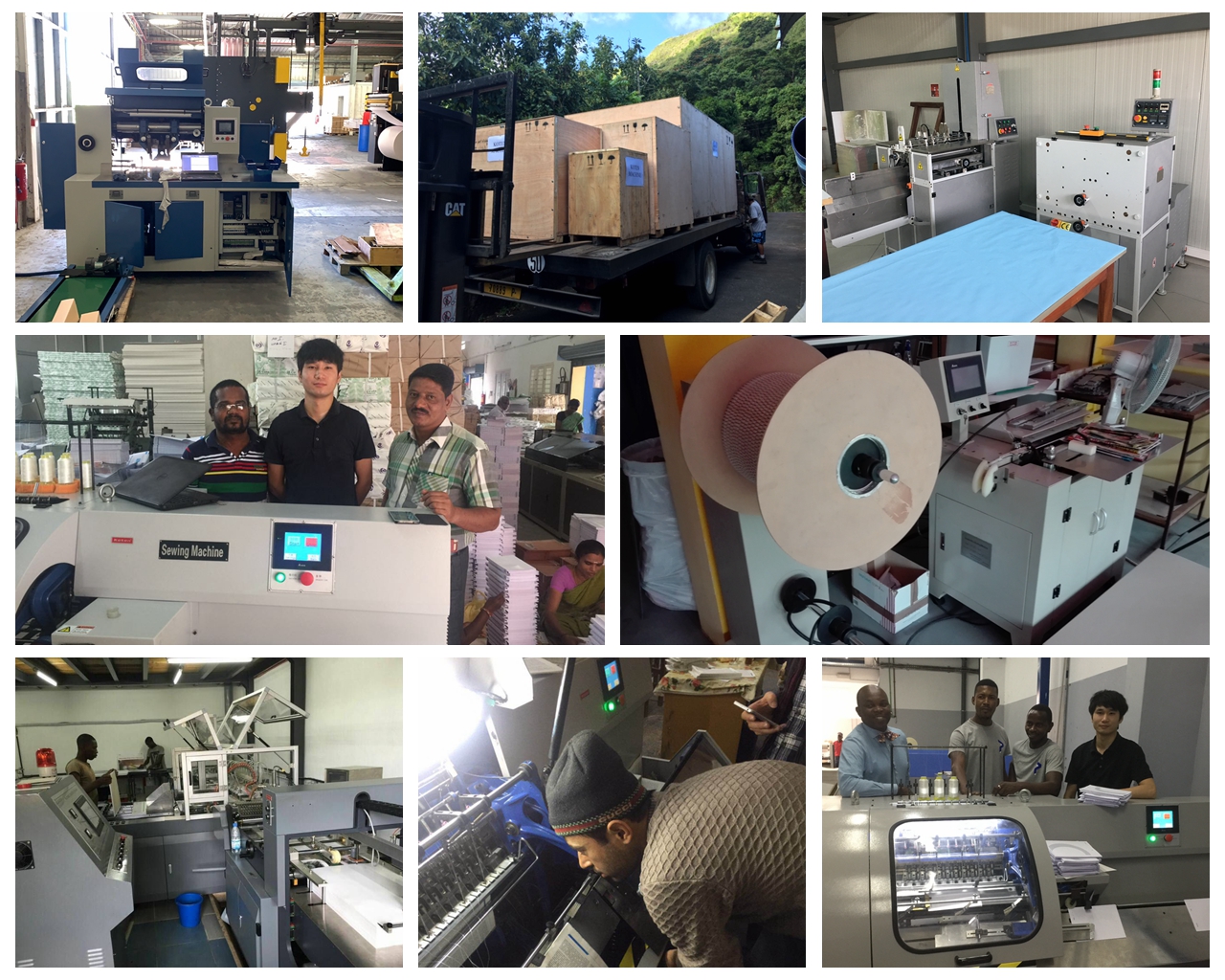

Koten Machines Container Loading.

140 Countries Clients Who Has Koten Brand Machines Till 2019.

2. Guarantee.

3. Delivery Time.

4. What is your package?

5. Do you have Installation and Training service if we bought the machines from your company?

6. Have you sold any machines to our country?

7. What is your payment terms?

8. What your company can offer?

Paper Bag Making Solutions.

Exhibitions and Customers'Meeting.

Factory Production.

Usage:

The machine applies to slit cellophane, PET, OPP, CPP, PE, PS, PVC and computer security labels, electronic computers, optical materials, film roll, foil roll, all kinds of paper rolls, film and printing of various materials.,etc

Main mechanical configuration:

1, Main body unit:

1. Machine’s main body adopts cast iron and steel structure.(cast iron after secondary operation and setting treatment)

2. Main driving roller adopts seamless steel pipe (after tempering, surface hardening, chrome plated, mirror surface, dynamic balance treatment)

3. Main driving press roller adopts rubber roll (nitrile-butadiene rubber)

4. Material guide rollers adopts steel rolls (aluminum alloy) and rubber roll (nitrile-butadiene rubber)

5. Driving mode of main body and rewind shafts adopt synchronizing wheel and belt.

2, Unwinding unit:

1. Unwind unit adopts one-piece structure.

2. It adopts removable bracket with ball slider.

3. Non-axial Air pressure and get way with Air Chuck, who is caught taking raw materials fast, easy loading, single-person operation

4. 1 set bias adjustable device can fine tune left and right, forward and backward through hand wheel.

5. Unwind tension’s actuator is 2 sets 50N/M magnetic powder brake. through PLC to achieve a constant tension.

6. EPC uses Germany brand E+L corrective device, it can achieve guide function by material’s edge

3. Rewinding unit:

1. Shafts adopt 3 inch pneumatic fall slip shaft which is controlled by proportional valve.

2. Lock mode adopts pneumatic control.

3. Rewind tension’s actuator is 2 sets Japanese brand SMC proportional valve. through PLC to achieve a constant tension.

4. Rewind press rollers provided by customers demand (2 sets)

5. Slitting knives are controlled by pneumatic cylinder (10 sets). Can be fine tuned. (Circle knife is optional).

6. Equipped with a vacuum-type waste edge exclusion system, use the strong force adsorb the waste edge out away

7. Equipped with a discharge rack which can provide a larger diameter of the finished product. Simple and efficient to operate and save time for the next feed.

4. Electrical equipment unit:

1. Main motor inverter adopts 1 pc Japanese brand Yaskawa vector inverter.

2. Main motor adopts 1 pc Germany brand Siemens vector motor.

3. Rewind motor inverter adopts 1 pc Japanese brand Yaskawa vector inverter.

4. Rewind motor inverter adopts 1 pc Germany brand Siemens vector motor.

5. EPC adopts analog control. Driving by servo motor through ultrasonic signal.

6. Adopts imported PLC to achieve accurate and stable control, true color touch screen display to enable simple and beautiful images. Interactive parameter setting the environment, eliminating the complicated configuration can start the job: The user pre-start only need to input the material thickness, width, density, diameter and speed parameters, the next will be done automatically by a computer calculation to complete.

7. With the functions of automatic and manual acceleration and deceleration.

8. Electrostatic elimination Unit(optional device): The machine equipped a group of static brush apart on up and down rewinding shaft , which can effectively eliminate the static between slitting and rewinding .

Main technical parameter:

Model | S400B-1100 | S400B-1300 | S400B-1500 | S400B-1700 |

Max. Speed | 400m/min | |||

Slitting Width | 30-1100mm | 30-1300mm | 30-1500mm | 30-1700mm |

Rewinding Diameter | 600mm | |||

Unwinding Diameter | 1200mm | |||

Slitting Precision | ±0.1mm | |||

Loading Weight | 1.5T | |||

Dimension | 4254×3300×1990 | 4454×3300×1990 | 4654×3300×1990 | 4854×3300×1990 |

Weight | 5.7T | 6T | 6.3T | 6.8T |

Power | 27KW | 29KW | 32KW | 34KW |

Power Supply | 380V/50HZ | |||

Applicable Materials | Aluminium Foil/PE/Self-adhesive paper/Kraft paper/Cardboard/Coated Paper and other paper products | |||

Main configuration:

Name | Brand | Origin | |

1 | PLC | Siemens | Germany |

2 | Servo Motor(Unwinding) | GTAKE 7.5KW | China |

3 | Servo Motor(Rewinding) | GTAKE 7.5KW | China |

4 | Frequency converter | GTAKE | China |

5 | Pneumatic components | AIRTAC | Taiwan |

6 | Proportional valve | SMC | Japan |

7 | EPC | ARISE | China |

8 | Bearing | NSK | Japan |

9 | Touch Screen | MCGS | China |

10 | Low Voltage Apparatus | Schneider | France |

11 | Button | Schneider | France |

Koten Machines Container Loading.

140 Countries Clients Who Has Koten Brand Machines Till 2019.

2. Guarantee.

3. Delivery Time.

4. What is your package?

5. Do you have Installation and Training service if we bought the machines from your company?

6. Have you sold any machines to our country?

7. What is your payment terms?

8. What your company can offer?

Paper Bag Making Solutions.

Exhibitions and Customers'Meeting.

Factory Production.

Sign up for our Zetor newsletter

Business Tel: +86-577-66887790

Fax: +86-577-65615260

E-mail: Master@cn-koten.com

Whasapp/Wechat/Mobile: +86-13958895259

Add:Room 402, Unit One, No.5 Building, North Sunshine Road, Anyang Street, Ruian City, Wenzhou, Zhejiang Province, China. ZIP. 325200