Views: 0 Author: Site Editor Publish Time: 2025-08-25 Origin: Site

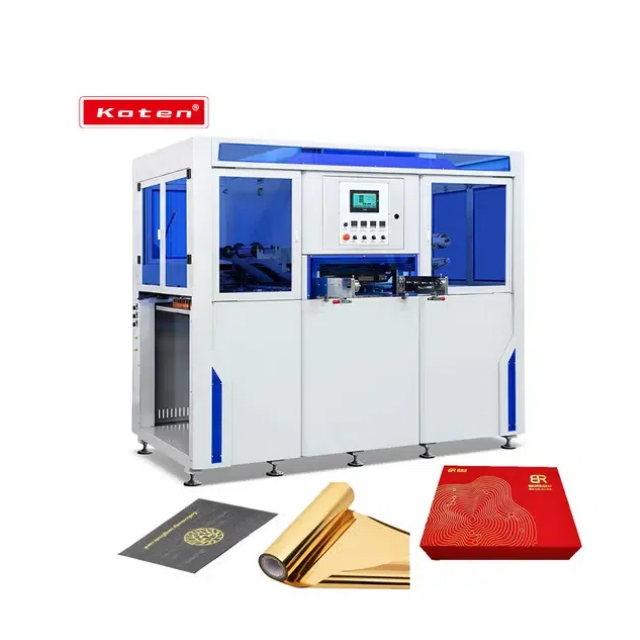

In the ever-evolving world of packaging, precision, efficiency, and versatility are more important than ever. As packaging requirements become increasingly sophisticated, companies are turning to specialized equipment to maintain a competitive edge. One machine that stands out in this domain is the Die Cutting Creasing Machine. At Koten Machinery, we have focused our expertise on designing machines that offer both cutting-edge functionality and long-term performance for businesses in printing and packaging. In this blog, we’ll explore what makes this machine essential for modern packaging workflows.

A Die Cutting Creasing Machine combines two essential functions into one efficient system—cutting and creasing. Unlike traditional cutters that only slice material into shape, this advanced machine not only defines the packaging's outer edges but also imprints precise crease lines that guide folds. This dual-action capability is crucial in modern packaging where structural integrity and clean presentation are non-negotiable.

While conventional rotary or manual cutters may suffice for basic tasks, they lack the integration and sophistication of a die cutting creasing system. This machine provides unmatched control over packaging design elements, making it ideal for creating high-quality cartons, folding boxes, and specialty packaging with clean edges and sharp folds.

Yes—creased lines determine the accuracy and strength of a fold. Without a proper crease, packaging materials, especially thicker boards, are prone to cracking, uneven folds, or structural weaknesses. A creasing machine uses calculated pressure to create an indentation, which serves as a guide for flawless folding. This not only maintains the aesthetics of the final package but also reinforces its functional integrity.

Though often used interchangeably, creasing and scoring differ in both technique and result. Scoring typically refers to a linear compression made using a wheel or blade, which may weaken the material over time. Creasing, on the other hand, involves displacing the material between male and female dies, ensuring a more durable and consistent result. This distinction is particularly relevant in luxury packaging and rigid box production, where durability and appearance are equally important.

Flatbed die cutters are particularly effective when working with heavy or multilayered materials like corrugated board, chipboard, or laminated sheets. These machines exert downward pressure through flat dies, resulting in cleaner cuts and more uniform creases. For businesses producing high-end packaging or industrial-grade boxes, this is a critical advantage.

Flatbed systems also allow for deeper creasing without tearing, which is essential in applications that require a luxury presentation, such as electronics packaging, cosmetics, or custom gift boxes. Koten Machinery’s flatbed models offer adjustable pressure settings to ensure material compatibility across a wide range of projects.

While rotary die cutters are favored for high-speed, large-volume operations with uniform designs, flatbed die cutters shine in medium-volume, complex, or custom jobs. Their flexibility in handling intricate patterns and variable run lengths makes them the preferred choice for small to medium enterprises and custom packaging manufacturers. Our machines are optimized for precision in short-run and mid-range production, allowing businesses to remain agile without compromising on quality.

Manual machines offer basic functionality but are labor-intensive and less consistent. They may be suitable for prototyping but fall short in scaling operations.

Rotary die cutters are designed for speed, making them suitable for bulk processing but less accurate with complex shapes or varying materials.

Flatbed die cutting creasing machines, by contrast, offer a balance of precision, pressure control, and format versatility. With programmable settings, accurate alignment systems, and die compatibility, they support high-quality production without the need for frequent manual adjustments.

Though flatbed systems may require a higher upfront investment compared to manual alternatives, their precision and efficiency reduce material waste and labor costs over time. At Koten Machinery, our machines are engineered with servo-driven feeders and automatic registration systems to streamline operations and minimize errors. This ensures faster turnaround with fewer defects—ideal for businesses aiming for professional-grade packaging with optimal resource use.

For small and medium-sized enterprises (SMEs), a Die Cutting Creasing Machine can level the playing field. It allows them to offer high-end packaging solutions without relying on outsourcing. With manageable machine sizes and intuitive control systems, our equipment is designed for easy integration into existing workflows.

Brands and designers working on bespoke packaging also benefit greatly. With rapid tool changeover and layout flexibility, designers can bring new packaging concepts to life efficiently. Whether it’s a one-off promotional box or a short-run specialty order, flatbed machines enable quick execution with professional outcomes.

When evaluating a die cutting creasing machine, certain features should be prioritized:

Feeding System: Look for automatic, servo-controlled feeders that handle various material sizes with minimal adjustment.

Control Panel: Touchscreen interfaces and programmable memory settings enable easier job management and reduce setup time.

Die Compatibility: Support for both steel rule dies and embossing plates offers versatility in packaging applications.

At Koten Machinery, we offer machines that meet these criteria with robust construction, precision engineering, and modular design for long-term flexibility.

As packaging demands evolve, so too does the technology that supports it. Trends shaping the future of die cutting creasing machines include:

Digital Workflow Integration: Machines that communicate with design software, enabling real-time adjustments and reduced prepress errors.

Automation: Automated stacking, stripping, and waste removal are becoming standard features in advanced models, increasing productivity.

Smart Monitoring: Sensors and data analytics provide performance insights, allowing for predictive maintenance and process optimization.

Koten Machinery is actively developing solutions in these areas to help customers future-proof their packaging operations.

In a competitive packaging landscape, precision, speed, and adaptability are no longer optional—they're essential. A Die Cutting Creasing Machine offers all these advantages and more, empowering businesses to deliver high-quality packaging that meets modern standards. Whether you're a growing SME, a custom packaging studio, or a print shop looking to expand, this machine can significantly improve your productivity and output quality.

At Koten Machinery, we’ve been committed since 2005 to providing intelligent solutions for the printing and packaging industry. Our die cutting and creasing machines are trusted across the globe for their reliability and performance. If you're ready to elevate your packaging capabilities, contact us today to learn more about our full line of machinery and how we can support your production goals.

Sign up for our Zetor newsletter

Business Tel: +86-577-66887790

Fax: +86-577-65615260

E-mail: Master@cn-koten.com

Whasapp/Wechat/Mobile: +86-13958895259

Add:Room 402, Unit One, No.5 Building, North Sunshine Road, Anyang Street, Ruian City, Wenzhou, Zhejiang Province, China. ZIP. 325200