Views: 0 Author: Site Editor Publish Time: 2025-11-27 Origin: Site

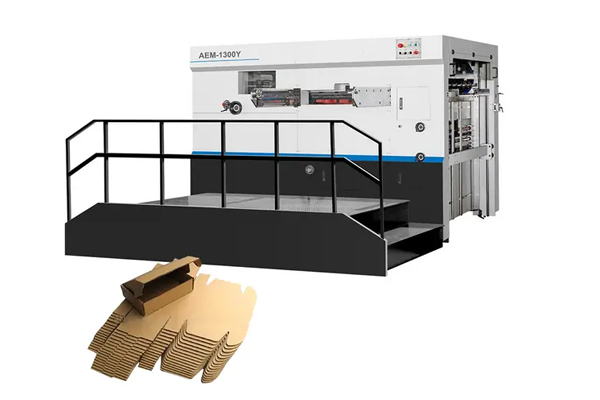

Die cutting is a versatile process used to cut a variety of materials into specific shapes. It plays a key role in manufacturing industries such as packaging, textiles, and electronics. In this article, we’ll explore the different types of die cutting machines, with a focus on Die Cutting Machines and electric die cutting machines, highlighting their advantages, applications, and the factors to consider when choosing the right machine for your needs.

Die cutting refers to the process of using a die to cut materials into specific shapes. The die, essentially a custom-shaped blade, applies pressure to a material such as paper, fabric, foam, or plastic to create the desired shape. The die cutting process can be likened to a cookie cutter; the material is placed under the die, which then presses down to cut through the material.

With various types of die cutting machines available in the market, choosing the right one depends on your production requirements, the material being used, and the complexity of the shapes to be cut. In this article, we will explore the different types of die cutting machines, including electric die cutting machines, which offer speed, efficiency, and automation.

Selecting the appropriate die cutting machine for your project is critical to achieving the desired results. Factors such as the production volume, material thickness, design complexity, and your overall budget must all be considered. Electric die cutting machines, for example, offer high-speed automation and consistency, making them an excellent choice for large-scale manufacturing processes. These machines can reduce manual labor, streamline workflows, and boost overall productivity.

The right machine will also ensure precise cuts, minimize material waste, and improve operational efficiency, making it essential to match the machine to your specific needs.

Flatbed die cutting machines are the most commonly used type in various industries. This type involves a flat surface where the material is placed, and the die presses down onto the material to make cuts.

High precision and accuracy, ideal for small to medium production runs.

Can handle thicker materials, such as chipboard and foam.

Flexible in terms of material types, such as paper, cardboard, and plastic.

Slower production speed compared to rotary die cutting machines.

Requires more manual setup time, which can increase production downtime.

Packaging designs, prototypes, and specialty boxes.

Small to medium-sized production runs for a variety of materials.

Rotary die cutting machines use cylindrical dies that rotate continuously, applying pressure to the material as it is fed through the machine. This method is often used for continuous production and large quantities of products.

High-speed cutting, perfect for high-volume production.

Ideal for cutting thin materials like films, labels, and foils.

Minimal material waste and high efficiency.

More expensive than flatbed die cutters due to the cost of rotary dies.

Less effective for thicker materials or irregular shapes.

High-volume production of labels, adhesives, and packaging.

Continuous cutting for flexible materials such as film and fabric.

Digital die cutting machines, also known as electric die cutting machines, use a computer-controlled system to cut materials. These machines are driven by electric motors, and the cutting design is programmed into the machine using CAD or graphic software.

Fast changeovers and minimal setup time, allowing for quick adjustment to design changes.

Highly versatile, capable of cutting a wide range of materials with ease.

Perfect for small to medium runs and custom designs, making it an excellent choice for prototyping.

Electric die cutting machines are more energy-efficient compared to manual counterparts.

Slower than rotary die cutting machines for large-scale runs.

May have limitations when it comes to very thick materials or certain types of substrate.

Customized packaging, short-run production, and prototyping.

Crafting, scrapbooking, and textile industries.

Laser die cutting machines use a high-powered laser to cut or engrave materials. This non-contact method allows for extremely precise cuts with minimal wear on the cutting equipment.

Extremely high precision and the ability to cut intricate designs and detailed patterns.

No tool wear, making it ideal for precision tasks.

Capable of cutting a wide range of materials, including textiles, wood, and acrylic.

Expensive initial setup and operating costs.

Slower speeds for large-volume production compared to mechanical die cutting machines.

Electronics manufacturing, foam cutting, and custom design work.

Ideal for high-end, intricate packaging and decorative items.

Besides the commonly used methods mentioned above, several specialized die cutting techniques exist. These machines include water jet cutting, semi-rotary machines, and roll-to-roll die cutting systems.

Uses a high-pressure stream of water mixed with abrasive material to cut through tougher materials. Ideal for thick, heavy-duty materials like metals.

Combines the benefits of both flatbed and rotary die cutting. Often used for producing labels and packaging in medium to high volumes.

Involves feeding the material through the machine in a continuous roll. This type of die cutting is typically used for cutting flexible materials such as plastic films, foils, and papers.

Industrial uses such as aerospace, automotive, and heavy-duty packaging.

High-volume production of flexible products and continuous roll materials.

Electric die cutting machines offer numerous advantages, especially in modern manufacturing environments. These machines are powered by electric motors and can be integrated into automated production lines. The automation provided by electric die cutting machines improves speed, accuracy, and consistency across a variety of industries.

For manufacturers dealing with high-volume production or rapid prototyping, electric die cutting machines are a preferred choice. They allow for quick changes between designs, reducing downtime and improving overall production flow. Additionally, electric die cutting machines tend to be more energy-efficient, which can help reduce operational costs.

Choosing the right die cutting machine depends on a variety of factors, including your production needs, budget, and material requirements. Consider the following criteria when selecting a machine:

Production Volume: If you have high-volume production runs, rotary or electric die cutting machines are ideal. For small to medium runs, flatbed and digital machines may be more suitable.

Material Type: Some machines are better suited for specific materials. For example, laser die cutting machines work well with delicate or intricate materials, while rotary machines are better for thin, flexible materials.

Design Complexity: If you need to cut complex shapes or intricate patterns, laser or digital die cutting may be your best option.

Budget: Electric and digital die cutting machines typically have higher upfront costs but can provide long-term savings through automation and reduced labor.

Blade Wear: All die cutting machines experience wear over time, especially rotary and flatbed types. Regular maintenance and blade sharpening can help maintain cutting precision.

Material Compatibility: Choosing the right machine for your material is key. For example, electric die cutting machines may not be suitable for very thick materials, while rotary machines work best for thin films.

Changeover Time: Machines like flatbed die cutters often have longer changeover times, but newer digital and electric die cutting machines reduce downtime significantly.

In summary, the choice of die cutting machine depends on a variety of factors, including material type, production volume, and desired precision. Electric die cutting machines stand out for their speed, automation, and versatility, making them a popular choice for industries that require quick changeovers and custom cuts. When selecting the right die cutting machine, consider your specific production needs and choose a machine that aligns with your goals.

Sign up for our Zetor newsletter

Business Tel: +86-577-66887790

Fax: +86-577-65615260

E-mail: Master@cn-koten.com

Whasapp/Wechat/Mobile: +86-13958895259

Add:Room 402, Unit One, No.5 Building, North Sunshine Road, Anyang Street, Ruian City, Wenzhou, Zhejiang Province, China. ZIP. 325200