Die cutting is a powerful manufacturing process that plays a critical role in various industries, from packaging to textiles. Whether you're creating intricate designs in paper, precise parts for the automotive industry, or cutting fabric for garments, die cutting machines are essential tools in achieving high-quality results with efficiency and consistency. In this article, we'll explore what die cuts do, how die cutting machines work, and why they are crucial for fabric cutting.

A die-cut is a method used to cut, shape, or form a material using a specialized tool known as a "die." This tool works like a cookie cutter, pressing down on the material to create a precise shape. The die can cut through a variety of materials, including paper, plastic, foam, and fabric. The die-cut process is widely used in industries that require high precision and uniformity in mass production.

Die cutting is a versatile process that can produce complex shapes and intricate designs, which are often difficult or time-consuming to achieve manually. Whether you're cutting a simple shape like a square or a detailed custom design, die cutting ensures that every piece is cut with the same high level of accuracy and consistency.

A die-cut machine allows manufacturers to quickly and efficiently cut materials into a wide range of shapes and sizes. Here’s a closer look at the key benefits of using a die-cut:

Precision and Uniformity: Die cutting machines provide precise cuts that are uniform across all products. This is essential when producing large volumes of the same item, such as labels, parts for assembly, or fabric components for garments.

Efficiency: The die-cutting process significantly reduces production time. Once the die is created, cutting becomes a fast and automated process, which is perfect for high-volume runs.

Versatility: Die cutting machines can handle a variety of materials, making them a go-to solution for many industries. Whether you are cutting paper, plastic, or fabric, die cutting provides versatility that many other cutting methods cannot match.

Cost-Effective: Despite the initial cost of the die itself, die cutting proves to be cost-effective for mass production. The speed and efficiency of the process make it more affordable than traditional manual cutting, particularly in large-scale operations.

Complex Shapes and Custom Designs: Die cutting enables the creation of intricate shapes that would be challenging to cut manually. It allows designers to explore creative possibilities, including custom logos, patterns, and shapes that can be used across multiple materials.

Die cutting machines are equipped with a die, which is a sharp, custom-shaped tool that presses into the material to create the desired shape. There are several types of die cutting machines, each suited for different needs.

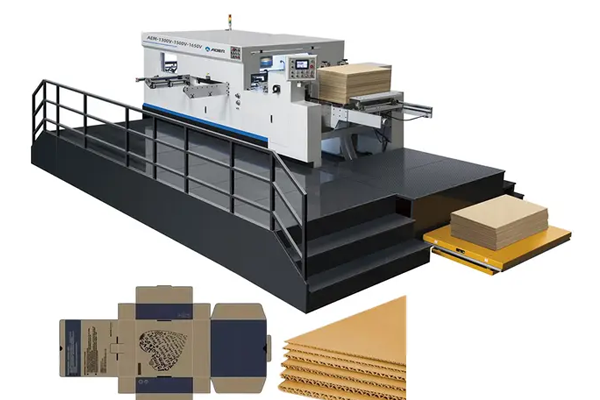

Flatbed die cutting machines are ideal for materials that need to be cut into specific shapes with high precision. This machine uses a flat surface to press the die into the material. It's commonly used for cutting thick or large sheets of materials, such as paperboard, fabrics, and leather.

Rotary die cutting machines use a rotating die and are typically used for high-volume production. These machines are faster and more efficient than flatbed machines, making them suitable for industries like packaging and textiles where large quantities of items need to be cut quickly.

In addition to the traditional rotary and flatbed machines, semi-rotary and digital die cutting systems have emerged. These machines combine the precision of traditional die cutting with the flexibility and speed of digital tools. They are especially beneficial in industries that require frequent design changes or custom orders, such as the fashion and garment industries.

Die cutting machines offer several advantages, making them essential for industries such as packaging, automotive, and textiles. Here are the key reasons why manufacturers choose die cutting:

One of the primary benefits of using die cutting machines is their ability to increase production speed. Die cutting can produce large quantities of pieces in a short amount of time, which is perfect for businesses that need to scale their production processes.

With die cutting, every piece that is produced is identical in size and shape. This consistency is essential when producing parts that must fit together perfectly, such as packaging materials or garment components. It also reduces the likelihood of human error, which can occur in manual cutting.

Die cutting machines are capable of cutting intricate and detailed shapes, even those that are complex or have curves. This makes them ideal for producing custom designs, logos, or other unique shapes that would be difficult or impossible to achieve manually.

In the textile industry, die cutting machines for fabric are incredibly useful. They can cut multiple layers of fabric simultaneously, saving time and labor costs. Whether you're cutting simple shapes or complex patterns, die cutting ensures that fabric pieces are uniform and ready for the next stage of production.

Die cutting is efficient in terms of material usage. The process allows for precise cuts, which minimizes waste and maximizes the yield from each sheet or roll of material. This is especially important in industries like fabric production, where material costs can be significant.

Despite its many benefits, there are some limitations to die cutting:

Upfront Tooling Costs: Custom dies can be expensive to create, especially for low-volume runs. However, for high-volume production, the cost of the die is typically justified by the savings in labor and materials.

Material Limitations: While die cutting can handle many materials, certain fabrics or substrates with irregular thickness may pose challenges. Additionally, delicate or stretchy fabrics might require special handling to prevent fraying or distortion.

Maintenance: Die cutting machines require regular maintenance to keep them functioning optimally. Over time, the dies can wear down and may need to be replaced, which can add to the operating costs.

Die cutting machines are especially beneficial for fabric cutting, where accuracy and efficiency are paramount. In the fashion and apparel industry, these machines are used to cut precise patterns and components like sleeves, collars, and pockets.

One of the most significant advantages of using die cutting machines for fabric is the ability to cut multiple layers of fabric at once. This not only speeds up production but also ensures that all pieces are identical in size and shape, which is essential for garment assembly.

Die cutting ensures that each fabric piece is cut with high precision, improving the overall quality of the garment. Consistency in fabric cutting reduces the chances of mistakes during the sewing process, which helps manufacturers save time and money.

By automating the fabric cutting process, die cutting machines eliminate the need for manual labor and reduce the risk of human error. This is particularly beneficial for high-volume garment production, where large quantities of fabric need to be cut accurately and quickly.

Here are viewpoints from different platforms and companies regarding die cutting and its role in manufacturing:

Blue Label Packaging: Die cutting is used to create precise, uniform cuts for packaging, labels, and various products, enhancing both aesthetics and functionality.

IQS Directory: Die cutting is described as a versatile process used to cut materials into specific shapes using a sharp tool, and it is beneficial for high-volume production, especially for materials like fabric.

Garment Technology Expo (GTE): The platform emphasizes die cutting’s importance in the garment industry for creating consistent, precise parts quickly, which is essential for mass production.

AccuShape Die Cutting: This company highlights how fabric die cutting can increase efficiency in textile production by cutting multiple layers at once and ensuring uniformity in every piece.

HFLaser: They explain that die cutting is a fast, efficient method for cutting fabrics into consistent shapes, especially for garments, and is preferable for large-scale fabric runs.

SBL Machinery: This company focuses on the various types of die cutting machines available, from flatbed to rotary, and how they cater to different materials, including fabric.

Die cutting is an essential process for many industries, including textiles, automotive, and packaging. It offers numerous advantages, including precision, speed, and the ability to handle complex shapes. Die cutting machines, particularly for fabric, provide manufacturers with a fast, efficient, and cost-effective way to cut multiple layers of material into uniform shapes. As the demand for custom designs and high-quality production grows, die cutting machines will continue to play a pivotal role in manufacturing processes worldwide.

Sign up for our Zetor newsletter

Business Tel: +86-577-66887790

Fax: +86-577-65615260

E-mail: Master@cn-koten.com

Whasapp/Wechat/Mobile: +86-13958895259

Add:Room 402, Unit One, No.5 Building, North Sunshine Road, Anyang Street, Ruian City, Wenzhou, Zhejiang Province, China. ZIP. 325200