Views: 0 Author: Site Editor Publish Time: 2025-10-08 Origin: Site

Die cutting technology plays a vital role in modern printing, packaging, and labeling industries. It allows manufacturers to transform plain sheets or rolls of material into precisely shaped products, enhancing both the appearance and functionality of packaging, labels, and promotional items. Beyond improving product quality, die cutting also significantly boosts production efficiency by streamlining repetitive cutting processes and minimizing manual labor.

Accurate and consistent cutting is essential in ensuring that each product meets high standards, whether it’s a luxury gift box, a decorative label, or a custom-printed packaging sleeve. With the growing demand for complex designs and precise finishes, businesses increasingly rely on specialized die cutting machines to maintain quality and speed.

So, what machines are commonly used in die cutting production? Which types are best suited for different materials, batch sizes, and design complexities? In the following sections, we will explore the main die cutting machines and their applications, highlighting how each type meets the diverse needs of modern manufacturing.

Roll-to-Sheet Die Cutting Machines are specifically designed to convert continuous rolls of material into precisely cut sheets. These machines are widely used in high-volume production environments where efficiency, consistency, and accuracy are critical. By integrating cutting, waste removal, and collection processes into a single automated workflow, they significantly reduce manual labor and production time.

Direct Roll-to-Sheet Conversion: The machine processes rolled material directly into finished sheets, eliminating the need for pre-cut boards.

Automatic Waste Removal: Excess edge material is trimmed and automatically wound up, reducing material waste.

Sheet Collection: Finished sheets are sorted and collected in real-time, allowing for immediate packaging or further processing.

High-Speed Production: These machines can operate at impressive speeds, often exceeding 200 cuts per minute, making them ideal for large-scale manufacturing.

Continuous Operation: The in-line design supports uninterrupted production, minimizing downtime and increasing overall output.

Reduced Labor Costs: Automation decreases the need for manual handling, saving both time and labor expenses.

Consistent Quality: Precision cutting ensures that every sheet meets exact specifications, maintaining uniformity across large batches.

Packaging Boxes: Ideal for corrugated or cardboard packaging, providing clean, precise cuts for folding and assembly.

High-Volume Printing Jobs: Suitable for producing promotional materials, brochures, or printed sheets in bulk.

Industrial Printing: Used in operations where speed and consistency are paramount, including labels and thin-board applications.

For businesses handling large quantities of printed or coated materials, roll-to-sheet machines from Koten Machinery offer a combination of efficiency, precision, and cost-effectiveness. Their fully automated process not only improves productivity but also ensures that material waste is minimized, supporting both economic and environmental sustainability.

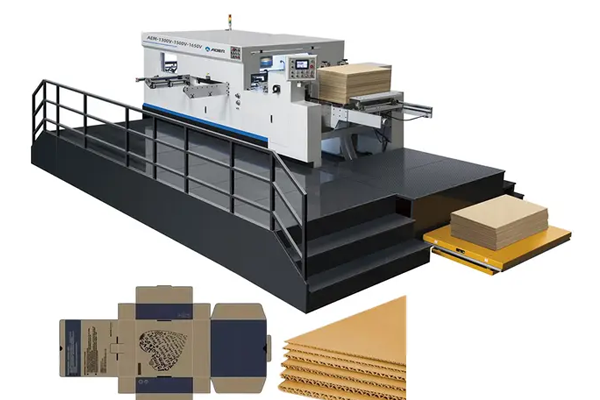

Flatbed Die Cutting Machines are designed to handle flat sheet materials with high precision and stability. Unlike roll-to-sheet machines, flatbed systems excel at cutting thicker materials or multiple layers simultaneously, making them ideal for high-quality packaging, book covers, and specialty printing. Their ability to integrate creasing and embossing functions ensures that products not only fit perfectly but also maintain an elegant, professional finish.

High-Precision Cutting: Flatbed machines provide accurate, repeatable cuts on a wide range of materials, from cardboard and gray board to coated paper.

Creasing and Embossing: Many flatbed models can perform creasing, embossing, and perforation in addition to standard cutting, adding versatility to the production process.

Multi-Layer Processing: Capable of cutting through several sheets or thicker boards at once, reducing production time for complex designs.

Thick Material Compatibility: Ideal for packaging applications that require strong, durable boards, such as rigid boxes or gift cartons.

Precision and Consistency: Ensures each cut aligns perfectly with pre-defined patterns, maintaining product quality across large batches.

Versatility: Supports various materials and functions, including die cutting, creasing, and embossing, allowing manufacturers to create intricate designs without additional machines.

Reduced Tool Wear: Advanced flatbed designs often include micro-adjustments for cutting pressure, prolonging die life and reducing maintenance costs.

Luxury Packaging Boxes: Perfect for producing high-end gift boxes that require precise cuts and elegant creases.

Book Covers: Ensures clean, consistent edges and folds for hardcover and softcover book production.

Specialty Printing: Suitable for custom invitations, decorative packaging, and intricate promotional materials.

Flatbed Die Cutting Machines from Koten Machinery combine precision, durability, and versatility. They are particularly well-suited for industries that demand high-quality finishes on thick or multi-layer materials. By using flatbed machines, businesses can achieve professional results efficiently while minimizing waste and ensuring consistent product standards.

Semi-Automatic Die Cutting Machines are designed to balance automation and manual control, making them ideal for smaller production runs or custom orders. While certain functions like cutting or creasing are automated, tasks such as feeding raw material or collecting finished sheets may require manual intervention. This hybrid design offers flexibility and cost efficiency for businesses that do not need full-scale automation.

Partial Automation: Automates essential cutting processes while allowing operators to manage feeding and collection.

Precision Cutting: Maintains accuracy even in smaller batch production, ensuring consistent product quality.

Customizable Operation: Operators can adjust settings for different materials, thicknesses, and designs, offering versatility for varied projects.

Flexibility for Small Batches: Ideal for limited runs, pilot projects, or special custom orders.

Cost-Effective: Lower investment compared to fully automatic machines, making it suitable for startups or small manufacturers.

Ease of Use: Operators can quickly adjust settings to accommodate different materials, sizes, and cutting requirements.

Versatile Applications: Can handle paper, cardboard, labels, and other thin to medium-thick materials.

Custom Labels: Produces small quantities of labels with precise shapes and sizes for niche markets or special products.

Small Batch Packaging: Ideal for custom packaging boxes, promotional materials, or limited edition products.

Prototyping and Design Testing: Useful for testing new designs before committing to full-scale production.

Semi-Automatic Die Cutting Machines from Koten Machinery offer a balance of efficiency, precision, and flexibility. They are particularly suitable for businesses that require reliable performance without the complexity or cost of fully automated systems. By using semi-automatic machines, manufacturers can maintain high-quality output while adapting quickly to small or customized production needs.

Hydraulic Label Die Cutting Machines are specialized for high-speed cutting of thin materials, making them ideal for labels, stickers, and small-format printing. These machines use hydraulic pressure to deliver precise, clean cuts, ensuring consistent quality even at high production speeds. Their efficiency and accuracy make them a popular choice for businesses focused on label and packaging production.

High-Speed Cutting: Capable of processing thin sheets or films rapidly while maintaining precise alignment.

Hydraulic Precision: Provides uniform cutting pressure across the entire material, reducing errors and material waste.

Thin Material Compatibility: Designed specifically for paper, film, or adhesive-backed substrates used in labels and stickers.

High Accuracy: Hydraulic systems ensure precise cuts, maintaining consistent size and shape for every label or sticker.

Versatility: Supports a wide range of thin materials, including coated papers, films, and laminates.

Labor Savings: Automation reduces the need for manual handling, lowering labor costs and improving production efficiency.

Fast Setup: Quick adjustments for different die shapes or material types enhance flexibility for varying production runs.

Label Printing: Produces precise and uniform labels for products ranging from cosmetics to beverages.

Stickers and Decals: Efficiently cuts small adhesive products for packaging or promotional use.

Thin Paper Packaging: Ideal for folding cartons, ticketing, or lightweight packaging materials.

Hydraulic Label Die Cutting Machines from Koten Machinery combine speed, precision, and versatility, making them the preferred choice for high-quality label production. Their ability to handle delicate thin materials efficiently reduces waste, improves output quality, and lowers operational costs, making them an essential asset for label manufacturers and small-format printing businesses.

The Auto Feed & Auto Collect Die Cutting Machine with Robot Arm represents the pinnacle of automation in die cutting technology. It integrates automated feeding, precision die cutting, and finished product collection into a single streamlined workflow. By utilizing robotic arms, this system can handle large volumes of material with minimal human intervention, making it ideal for high-capacity production lines.

Full Automation: Handles raw material feeding, die cutting, and finished sheet collection without manual operation.

Robotic Precision: Robotic arms ensure accurate placement and collection of sheets, maintaining consistent product quality.

Real-Time Sorting: Finished sheets are sorted and stacked automatically, ready for packaging or secondary processing.

Maximized Production Efficiency: Continuous operation reduces downtime and significantly increases output capacity.

Reduced Labor Costs: Automation minimizes manual intervention, allowing operators to focus on monitoring and quality control.

Consistent Product Quality: Precise handling and cutting ensure uniformity across every batch.

Versatility: Capable of processing various materials and sheet sizes, making it suitable for diverse industrial applications.

Large-Scale Production Lines: Perfect for manufacturers producing high volumes of packaging, labels, or printed sheets.

Batch Production: Ideal for operations requiring consistent output across multiple shifts or high-volume campaigns.

Automated Packaging Operations: Streamlines downstream processes by delivering pre-cut sheets ready for assembly or printing.

Koten Machinery’s Auto Feed & Auto Collect Die Cutting Machines with Robot Arms deliver unparalleled efficiency, precision, and reliability. By combining full automation with robotic handling, these machines minimize waste, reduce labor dependency, and ensure consistent high-quality output. For businesses aiming to scale production and maintain strict quality standards, these machines provide a comprehensive solution that meets modern industrial demands.

Selecting the appropriate die cutting machine is essential for ensuring efficiency, quality, and cost-effectiveness in production. Several key factors should be evaluated before making a decision:

Different materials require different cutting technologies. Thin papers or films are best suited for hydraulic or roll-to-sheet machines, while thick boards, multi-layer sheets, or specialty materials like leather may require flatbed or semi-automatic machines. Understanding the material properties ensures precise cuts and minimizes waste.

Small Batch Production: Semi-automatic or flatbed machines are ideal for custom orders or limited runs, providing flexibility without excessive investment.

Large Batch Production: Fully automatic machines, such as roll-to-sheet or robot-arm integrated systems, maximize efficiency and throughput for high-volume operations.

Simple cut-outs can be handled by most standard die cutting machines. However, intricate designs that include creasing, embossing, or concave/convex effects require machines with advanced capabilities, such as flatbed or hot foil stamping integrated systems.

The choice between manual, semi-automatic, and fully automatic machines depends on labor availability, production scale, and desired efficiency. Full automation reduces human intervention, improves consistency, and accelerates production, while semi-automatic machines offer flexibility and cost-effectiveness for smaller operations.

Die cutting machines are essential tools in modern printing, packaging, and labeling industries, offering precise cuts, consistent quality, and enhanced production efficiency. From roll-to-sheet machines for high-volume packaging, flatbed machines for thick or multi-layer materials, to semi-automatic and hydraulic label machines for small batches or thin substrates, each type serves unique production needs. Advanced solutions like auto-feed and robot-arm integrated machines provide full automation, reducing labor costs while maximizing output.

When selecting a die cutting machine, businesses should consider factors such as material type, batch size, product complexity, and automation level to ensure optimal results. Choosing the right machine not only improves efficiency but also minimizes waste and maintains high product quality.

For manufacturers looking for reliable, versatile, and high-performance die cutting solutions, Koten Machinery offers a comprehensive range of machines designed to meet diverse industrial requirements. Their machines deliver precision, speed, and durability across applications from small-scale custom projects to large production lines. Explore Koten Machinery’s offerings to find the ideal die cutting solution for your business and connect with their experts for professional guidance and support.

Sign up for our Zetor newsletter

Business Tel: +86-577-66887790

Fax: +86-577-65615260

E-mail: Master@cn-koten.com

Whasapp/Wechat/Mobile: +86-13958895259

Add:Room 402, Unit One, No.5 Building, North Sunshine Road, Anyang Street, Ruian City, Wenzhou, Zhejiang Province, China. ZIP. 325200